BIG BUSINESS – IBC FILLING

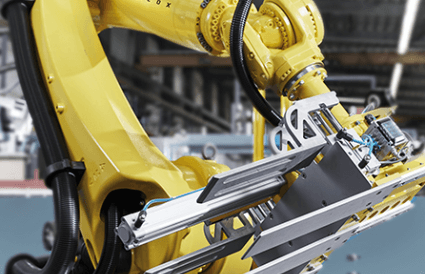

These plants are available as semi-automated stand-alone plants (combined with palette conveyor technology), as automated, and as fully automated filling plants with opening and sealing operations. Our particular strength lies in the individual filling of various products or product groups.