VeloVac means future technology for innovative powder bagging

In a groundbreaking project, we used our VeloVac technology to revolutionize the packaging of carbon black - a critical ingredient for the production of lithium-ion batteries. Traditional bagging methods were characterized by high levels of dust and inefficient handling, which not only led to environmental and health risks but also increased operating costs.

Compacting the powder using VeloVac technology makes it easier to handle without impairing material properties such as conductivity or solubility during further processing.

Read about the successful installation and handover of the VeloVac to our customers

The VeloVac solves your biggest production and business management problems when bagging light powder

Problem solver VeloVac

With VeloVac technology, you can save up to 70% on logistics costs and CO2 emissions. The maximum compaction of the powder reduces transport volumes, which significantly reduces both the number of transports and CO2 emissions.

Health risks for employees due to dust exposure

Minimizing health risks and protecting employees

Implementing the VeloVac machine creates a greener and safer work environment. CIP (Clean in Place) technology allows for effective cleaning without disassembly, minimizing exposure to hazardous substances.

Unpredictable machine downtimes and enormous maintenance costs

Reduction of operating costs

The integrated vacuum pump leads to a reduction in energy costs by 30 percent. This combined with a full-line automated system and the ability to reduce errors and failures contributes significantly to reducing the total cost of ownership.

Excessively high operating costs for warehouse and logistics

Efficient packaging processes and warehousing

VeloVac allows for significant product compaction, resulting in more compact, cleaner and tighter packages. This results in significant savings in logistics and storage costs while improving the pallet appearance.

Faulty, inferior and unsustainable brand image

High sustainability and customer satisfaction

By improving its CO2 balance and reducing its environmental impact, the company is sending a strong signal towards sustainability. The high product quality and product safety combined with the efficiency of the bagging machine lead to increased customer satisfaction and positive branding effects.

Compatible extensions

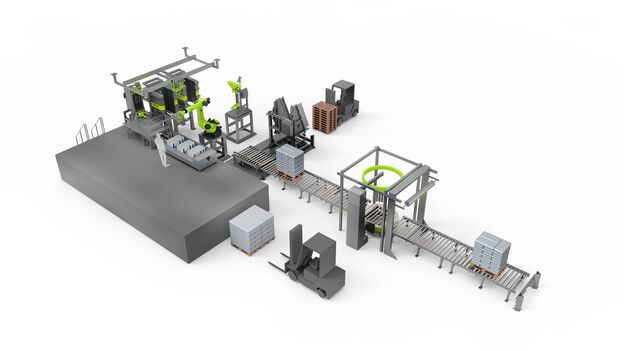

Interactive 3D animation of a VeloVac full-line system

Experience and explore in 3D

It's worth the wait: After the 3D animation has loaded, you can explore it using the mouse pointer and mouse wheel (zoom). Don't miss out on that buttons to click.

As part of a closed production system, our bagging machines go far beyond the pure bagging function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and bagging to post-processing and storage, which makes us a holistic system provider in production technology. The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

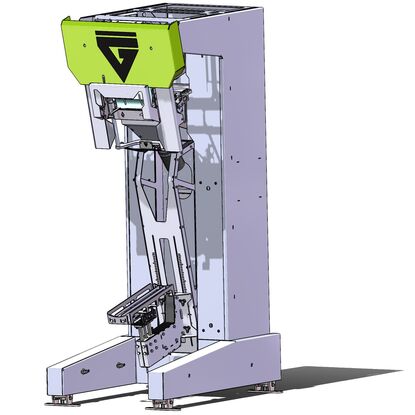

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

Our GREIF-VELOX vacuum bagging machines