Customers in

92 countries

> 92 % customer loyalty

for follow-up projects

Certified according to

ISO 9001 & 14001

24-hour service

365 days a year

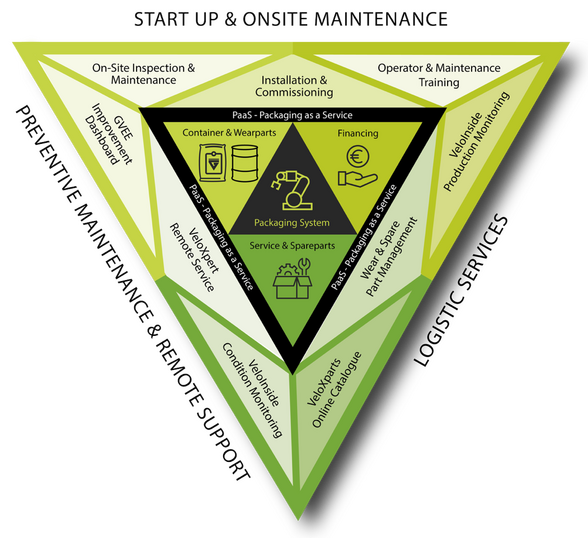

The VeloXpert program: our 360° service promise

With VeloXpert, we offer you more than just service - we offer a partnership. This programme covers all points of contact in the life cycle of your machine, from commissioning and predictive maintenance to continuous optimization. All our services are designed to safeguard your production, increase efficiency (OEE) and guarantee you maximum predictability.

At your side for the life of the machine

-

Concept & Design

Service expertise flows into the planning right from the start.

-

Factory Acceptance Test (FAT)

We ensure that your system meets the requirements at our factory. This guarantees smooth commissioning at your site.

-

Setup & commissioning

Our specialists install the machine at your site and ensure a perfect production start (Site Acceptance Test, SAT).

-

Operation & Optimization

We support you with service level agreements (SLAs), 24-hour remote service and proactive readjustments to improve performance.

-

Service & maintenance

Regular inspections and the replacement of OEM wear parts ensure longevity and performance.

-

Electronic spare parts catalog

Simple search and fast ordering of the right spare parts.

-

Predictive Maintenance

With systems such as VeloGuard, we monitor critical components automatically: a service before the fault that prevents failures before they even occur.

-

Repair & troubleshooting

Our helpdesk solves up to 95% of all faults remotely. If necessary, our technicians will be with you as quickly as possible.

-

Modernization & Retrofit

We make your machine fit for the future by replacing outdated components and integrating new technologies.

Our service modules for your success

Machine modernization & retrofit

Secure your production, even if manufacturers discontinue components such as the Siemens OP control system or Bizerba ST weighing technology. We equip your system with the latest technology and ensure the supply of spare parts for over ten years.

Increased operational safety

Continuous availability of spare parts

Integration into modern ERP systems

Predictive maintenance with VeloGuard

Avoid unplanned downtimes with automatic wear monitoring. Our VeloGuard system automatically checks compressed air-operated shut-off devices and reports the need for replacement directly on the system's HMI.

No more time-consuming trouble

Reliable production times

Downtimes can be planned

Electronic spare parts catalog

Find original spare and wear parts quickly and accurately in our digital catalog. Individually tailored to your machine.

Express delivery service

High-quality OEM parts

Minimization of production downtimes

Service & maintenance

Troubleshooting & 24h support

The perfect start to a long partnership

A successful Factory Acceptance Test (FAT) is the foundation for maximum machine availability. Here you can see how we create the basis for long-term efficient production for our customers in the chemical and food industries.

Dust-free production in the specialty chemicals industry

Customer: Cabot BV (Botlek)

Machine: Full-line solution with VeloVac vacuum packer

Project: Realization of a dust-free bagging system for ultra-light powders such as carbon black, accepted in a successful FAT

Service aspect: The clean, dust-free VeloVac technology not only ensures product quality, but also significantly minimizes ongoing cleaning and maintenance work.

Maximum performance and safety for food

Customer: Daesang Corporation

Machine: Quadruple version of the BVPV gross pneumatic packer

Project: Installation of a high-performance line (600 bags/h) with food-grade components and integrated combination checker for quality control

Service aspect: Integrated weighing and metal ejection guarantee maximum product safety, the function of which is permanently ensured by our regular service checks and calibrations.

Fully automatic and ATEX safety

Customer: Allnex

System: Two fully automatic filling machines of the type A-DOS-P1

Project: Commissioning of a full-line solution with robot labeling and load securing for use in ATEX zones

Service aspect: ATEX certification guarantees maximum occupational safety. Our service team provides support with the regular, legally required inspections in order to maintain this standard over the entire service life of the machine.

The next level of service: Packaging as a Service (PaaS)

Convert high initial investments (CAPEX) into predictable monthly operating costs (OPEX)

For bagging ultra-light powders, we go one step further with our PaaS model. Instead of buying a machine, you get a complete end-to-end solution at a fixed monthly price. We bundle machine provision, financing, maintenance, spare parts and even the appropriate consumables such as high-performance bags from dy-pack. This allows you to concentrate fully on your core business while we manage your packaging processes.

Full cost control:

A fixed monthly price for maximum predictability

No capital commitment:

Avoid high initial investments and protect your budget

All-round carefree package:

We take care of installation, maintenance and the supply of spare and consumable parts

Flexible packages:

Choose the model that suits you:

Total Care: Financing, service, bags and all parts

Essential Care: Service, bags and parts without financing

Individual Care: A freely selectable combination of services

Click here to go directly to your service and spare parts contact

Direct contact to GREIF-VELOX: Here you will find your contact person.

Find your contact person