The customer

AKD Toftlund is part of the KMC Group (“KartoffelMelCentralen”), a Danish association of potato starch producers founded in 1933.

Today, KMC sells over 60 different potato-based products in around 80 countries - over 90% of the products are exported, one of the largest customers being China.

The starting point

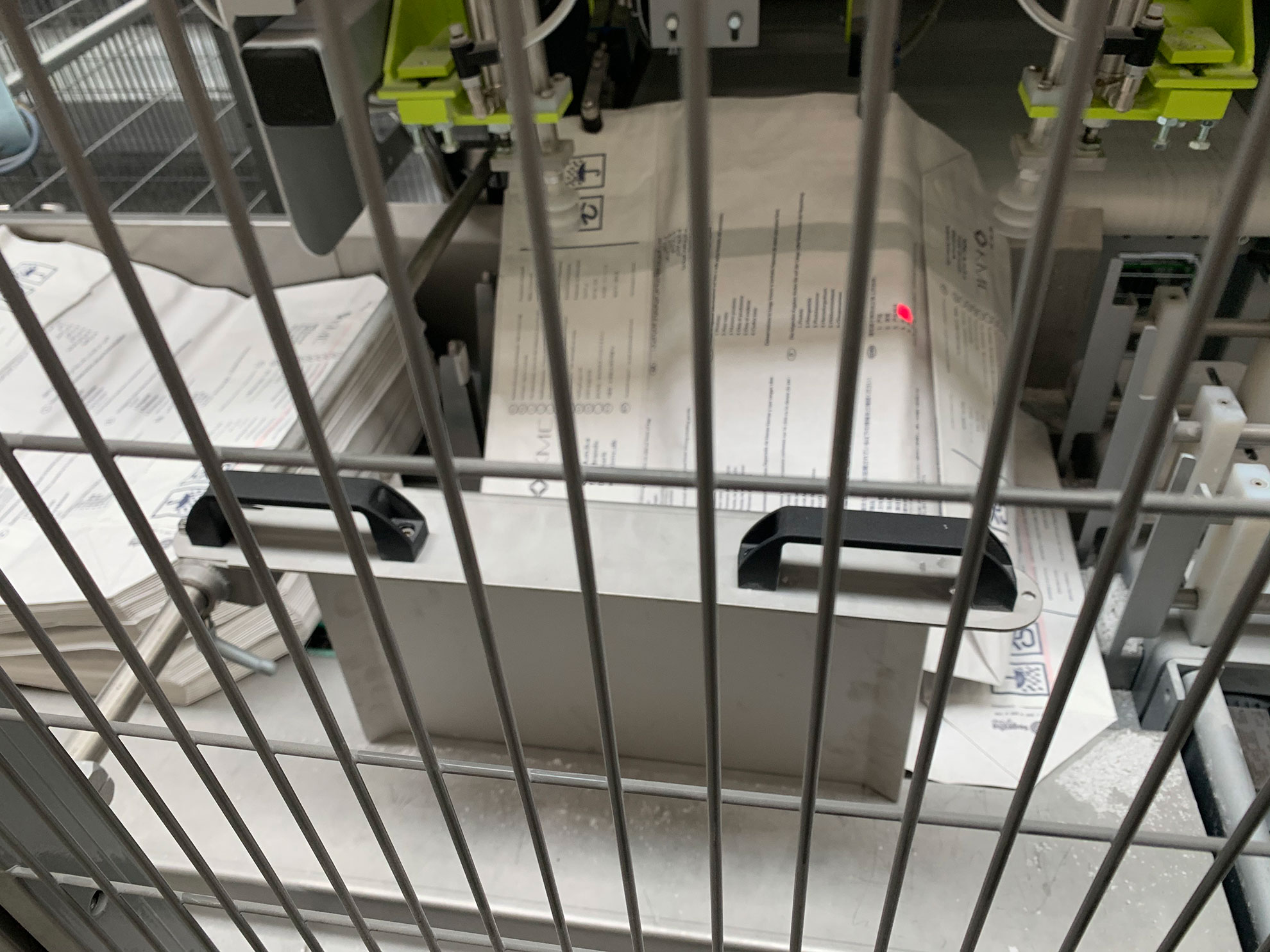

Since 2020/2021, AKD Toftlund has been operating two bagging lines at the Toftlund site, each equipped with a GREIF-VELOX BVPV 4.40 gross pneumatic packer and four bagging spouts. This is used to process potato starch and modified starch at a rate of up to 800 × 25 kg bags per hour. However, there were repeated instances of individual bags not being correctly captured and bagged - they stuck to the valve base and led to product loss, dust formation and increased cleaning effort.

The challenge

Classic valve packers only recognize the open valve after it has been placed on the nozzle and then start the bagging process - however, if the valve sticks, this leads to:

- incomplete bagging and contamination

- increased waste and dust exposure

- significantly higher cleaning costs

The aim was therefore to automatically identify and sort out faulty bags before bagging or sealing.

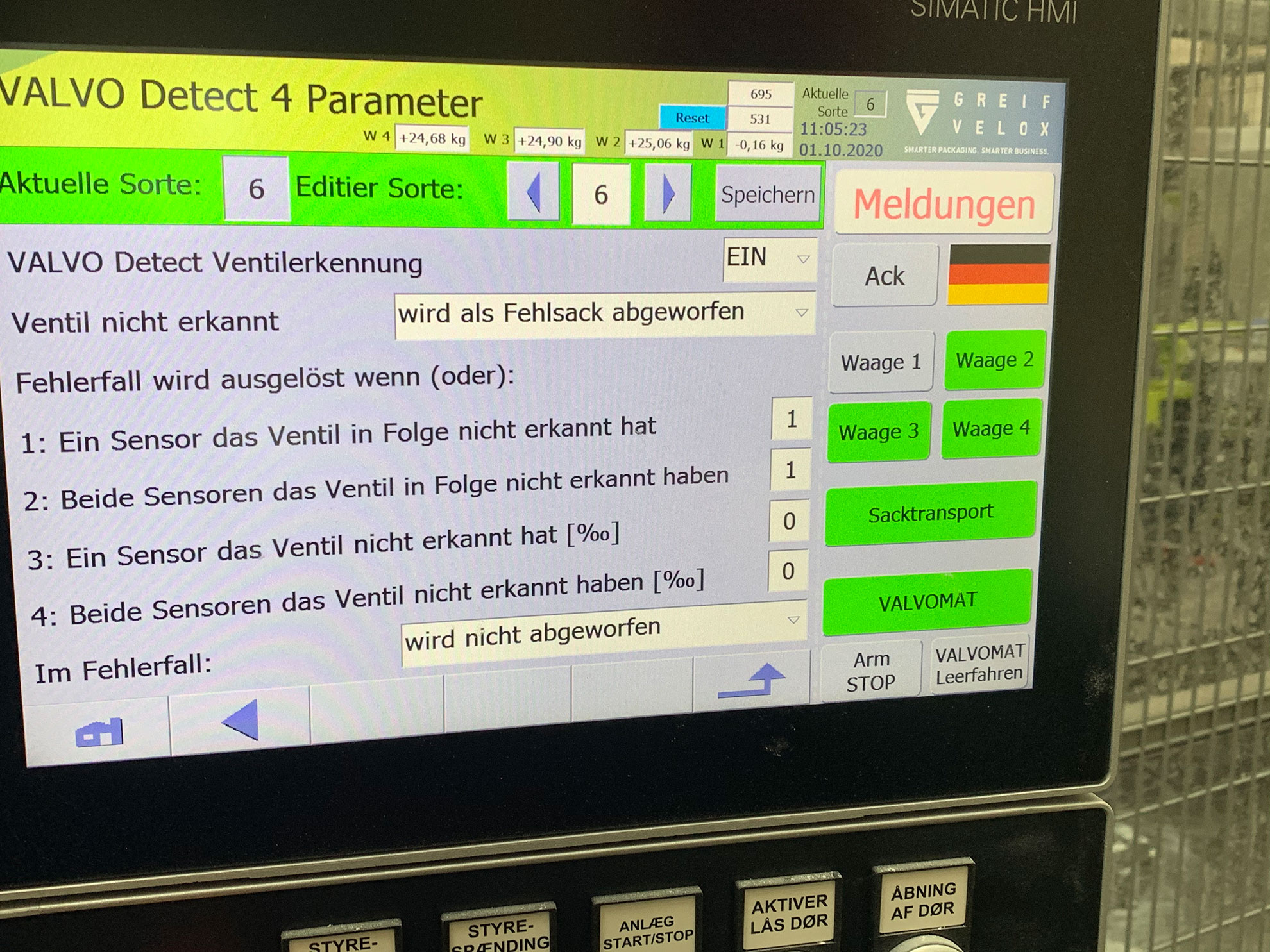

The solution: GREIF-VELOX ValvoDetect

GREIF-VELOX expanded the BVPV 4.40 to include the high-precision ValvoDetect sensor system, which works in two test stages:

- Variant Save:

Even before the bagging process, optical sensors check whether the bag valve has been opened correctly as soon as the bag sits on the spout. Faulty bags are ejected immediately. - Variant Clean:

Before the sealing process, ValvoDetect ensures that the bag is positioned exactly between the sonotrode and anvil. Incompletely positioned bags are also sorted out so that only perfectly sealed bags are placed on the pallet.

The result:

AKD Toftlund started an optimization project together with KMC Purchasing, Karup Kartoffelmelfabrik, GREIF-VELOX and the bag manufacturer using the data sorted out by ValvoDetect. Valve lengths and glue point modifications were varied in several series of tests. The result:

- Scrap reduction of up to 95 % (from 0.4-0.8 % to 0.04-0.08 %)

- Elimination of all incorrectly sealed bags thanks to clean inspection

- Significantly less cleaning effort and reduced dust exposure

- Stable throughput performance without unplanned disruptions

“We have no bags that are not properly sealed,” says John Skriver Kloster, Project Manager and Head of Process Technology Development at AKD Toftlund.

“It is very beneficial for the overall function of the system that we have ValvoDetect – it automatically sorts out faulty bags before bagging and palletizing.”

It is very beneficial for the overall function of the system that we have ValvoDetect – it automatically sorts out faulty bags before filling and palletizing.

John Skriver Kloster,

Project Manager and Head of Process Technology Development at AKD Toftlund

Up to 95 % less material waste

No complaints due to clean valve bags

Maximum system availability

Data-based process optimization at the touch of a button