The Digital Future of Powder and Liquid Filling: Our Partnership with ei³

Together with ei³, we are driving the digitalization of industrial packaging processes worldwide.

To future-proof our technologies for powder and liquid filling, GREIF-VELOX has entered into a strategic partnership with ei³ Corporation, a global leader in secure IIoT and AI solutions headquartered in New York, USA.

Why We Rely on IIoT and AI

As a manufacturer of highly specialized packaging systems for powders and liquids, we know that only intelligent connectivity enables processes to be managed efficiently, transparently, and proactively.

Together with ei³, we are developing digital solutions that allow our customers to monitor production lines in real time, detect maintenance needs at an early stage, and use operating data for continuous optimization – securely, scalably, and globally deployable.

VeloXpert + ei³: Digital Services with Real Added Value

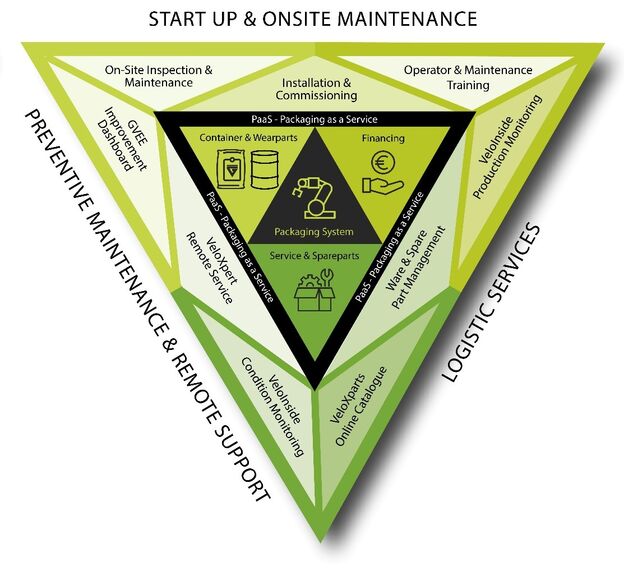

At the heart of our digital transformation is VeloXpert, GREIF-VELOX’s comprehensive service program.

In combination with ei³’s secure gateways and data platform, it forms a seamless solution for data-driven performance improvement:

- Machine and process data are systematically collected

- Visualized via the VeloInside Dashboard

- And used for maintenance, optimization, and production planning

For companies with a high degree of automation and a strong focus on efficiency, this solution provides a clear competitive advantage – enabling faster decision-making, predictive maintenance, and measurable productivity gains.

Predictive Maintenance and GVEE: Making Efficiency Measurable

What does that mean in practice? Operators can identify when processes begin to lose efficiency or when downtime is imminent. Maintenance requirements are predicted before unplanned stops occur. Production lines can be analyzed in real time and continuously improved – in terms of both quality and resource utilization.

A key performance indicator in this context is the Greif-Velox Equipment Effectiveness (GVEE). Based on the established OEE (Overall Equipment Effectiveness) framework, GVEE expands it with process-specific factors relevant to powder and liquid filling. This creates a more precise picture of actual system performance – and a solid foundation for data-driven decision-making.

Security Through Zero-Trust Architecture

Thanks to ei³’s Zero-Trust Architecture, all data is protected at all times – even within complex, heterogeneous machine environments. All data traffic between the machine, gateway, and cloud is encrypted and secured through multi-layered security mechanisms.

Packaging Expertise Meets Digital Intelligence

Combining our packaging technologies with ei³’s secure, IIoT-based gateways and AI technologies represents a decisive step forward in digitally connected efficiency.

Through this partnership, we are establishing the foundation for data-driven process optimization, increased operational reliability, and sustainable resource utilization – fully in line with our three core values: Efficiency, Innovation, and Reliability.