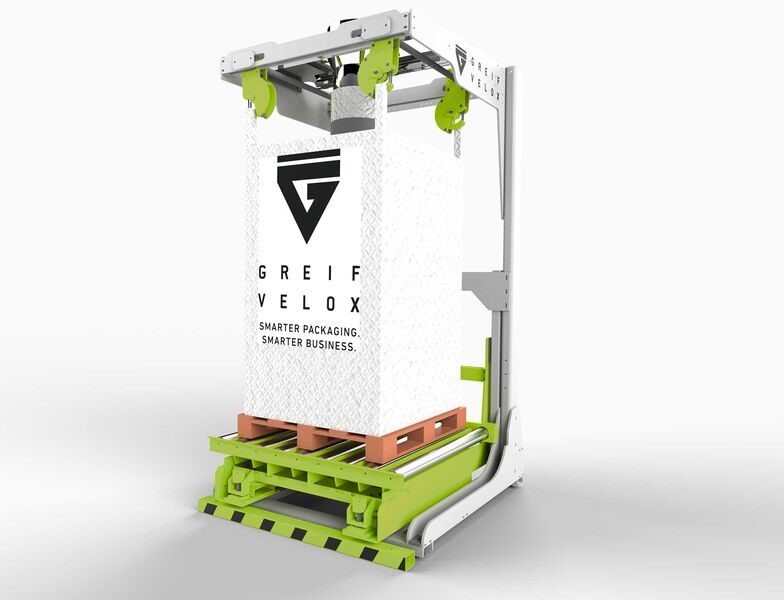

Produktdaten der FIBC Abfüllanlage

| Gebinde | FIBC |

|---|---|

| Medium | Pulver mit geringem Schüttgewicht und hohem Lufthaltevermögen |

| Korngrößen | mit weniger als 200 µm: Industrieruß (Carbon Black), pyrogene Kieselsäure, Farbpigmente, Silica, Pflanzenschutzmittel, Graphit, Dispersionspulver und Titandioxid |

| Branche | Chemie |

| Leistung | bis zu 10 FIBCs pro Stunde |

Optimieren Sie Ihre Schüttgutabfüllung mit der FIBC Abfüllanlage

Optimierte Schüttgutabfüllung

Ineffiziente manuelle Abfüllprozesse mit extrem hohem Fehlerrisiko

Vollautomatisierte Abfüllvorgänge reduzieren Fehlermargen und steigern die Produktionseffizienz.

Zeitaufwändige Einrichtungszeiten für verschiedene Produkte

Schnelle Umstellung und einfache Konfiguration durch benutzerfreundliche Schnittstellen und programmierbare Logiken.

Gesundheits- und Sicherheitsrisiken durch Staub und Kontaminanten

Verbesserte Gesundheits- und Sicherheitsbedingungen durch ein geschlossenes, kontaminationsfreies System.

Hohe Betriebskosten durch Ausfallzeiten infolge von Wartungsarbeiten

Reduzierte laufende Kosten und erhöhte ROI dank langlebiger Konstruktion und geringem Wartungsbedarf.

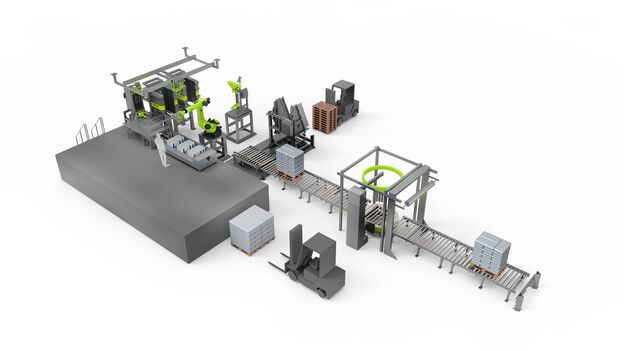

Als Teil eines geschlossenen Produktionssystems gehen unsere Abfüllanlagen weit über die reine Abfüllfunktion hinaus: Sie bilden einen integralen Teil eines Gesamtsystems, das sich nahtlos in bestehende Produktionslinien einfügt und diese ergänzt.

Unsere Full-Line-Anlagen sind in der Lage, komplexe Anforderungen von der Gebindebereitstellung über die Abfüllung bis hin zur Nachbearbeitung und Lagerung zu bedienen, was uns zu einem ganzheitlichen Systemanbieter in der Produktionstechnik macht. Dabei steht die individuelle Anpassung im Vordergrund, um eine optimale Integration in die jeweiligen Betriebsabläufe zu gewährleisten.

Mit Standardlösungen sparen Sie Geld.

Mit individuellen Lösungen verdienen Sie Geld.

Unsere Philosophie bei Greif-Velox ist es, individuell zugeschnittene Lösungen statt Standardprodukte zu bieten.

Jede Abfüllanlage wird genau auf die Bedürfnisse und Prozesse unserer Kunden abgestimmt, um eine schnelle Integration in bestehende Produktlinien oder die Entwicklung einer vollständig abgestimmten Full-Line-Anlage zu ermöglichen.

Wir legen großen Wert auf Präzision, Sicherheit und Automatisierung, um die Produktionseffizienz unserer Kunden bei maximaler Flexibilität zu steigern.

Finden Sie den richtigen Ansprechpartner

Direkter Kontakt zu GREIF-VELOX oder kompetenter Handelspartner bei Ihnen vor Ort:

Hier finden Sie den richtigen Ansprechpartner für Ihr Anliegen.

Weitere Greif-Velox-FIBC-Abfüllanlagen