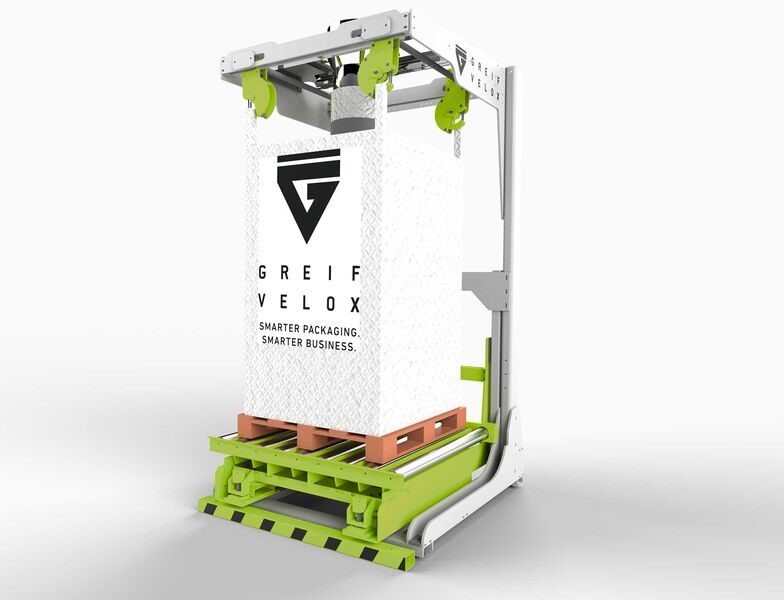

Product data of the FIBC filling system

| Container | FIBC |

|---|---|

| Medium | Powder with low bulk density and high air holding capacity |

| Grain sizes | with less than 200 µm: carbon black, fumed silica, color pigments, silica, pesticides, graphite, dispersion powder and titanium dioxide |

| Industry | Chemistry |

| Performance | up to 10 FIBCs per hour |

Optimize your bulk filling with the FIBC filling system

Optimized bulk filling

Inefficient manual filling processes with an extremely high risk of errors

Fully automated filling processes reduce error margins and increase production efficiency.

Time-consuming setup times for different products

Quick changeover and easy configuration through user-friendly interfaces and programmable logic.

Health and safety risks from dust and contaminants

Improved health and safety conditions through a closed, contamination-free system.

High operating costs due to downtime due to maintenance work

Reduced running costs and increased ROI thanks to durable construction and low maintenance requirements.

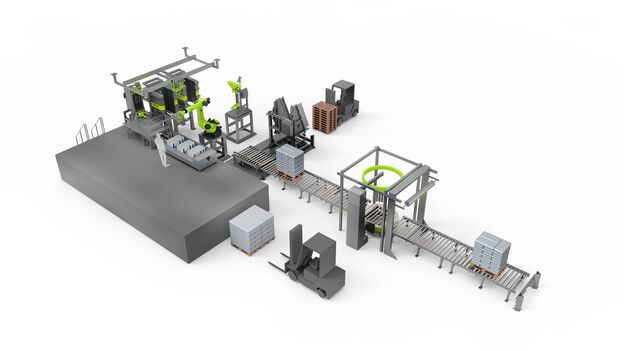

As part of a closed production system, our filling systems go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology. The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

More Greif-Velox FIBC filling systems