News

view all newsUpcoming Events

view all eventsNuremberg, 09/23/2025 - 09/25/2025

Las Vegas, 09/29/2025 - 10/01/2025

Efficient and flexible filling solutions

Chemicals, petrochemicals and food industry

Chemistry

Precise, safe and efficient processes are the foundation of the chemical industry. GREIF-VELOX offers sophisticated filling and packaging solutions that have been specially developed for handling a wide range of liquids, including granulates.

Petrochemistry

Our filling solutions for the petrochemical industry are robust, powerful and adaptable. From handling highly viscous products to explosive substances. GREIF-VELOX filling systems guarantee contamination-free filling and minimize the risk of product leakage.

Food

Hygienic, accurate and reliable - crucial in the food industry and embodied by GREIF-VELOX. Adapted to the high safety standards for food safety, our filling solutions enable precise filling of substances without compromising on product quality.

System development: Full-line systems for customized complete production chains

Complete solutions for your individual production requirements

Our full-line systems are the optimal choice for companies that are either starting a new line of production or intend to completely overhaul their existing packaging and filling systems.

The most significant advantage of our full-line systems is the holistic view and implementation of your production process.

We don't just offer individual machines, but a fully integrated solution that is tailored precisely to your needs and requirements. This also includes the specification, delivery and integration of all necessary components, including those from third parties.

From the initial planning phase to implementation and ongoing maintenance - everything is delivered from a single source, which not only saves time and money, but also significantly reduces the complexity of working with different suppliers and technologies.

Full-line systems

from GREIF-VELOX

in moving images

Simplify operating processes

by reducing the number of interfaces between the systems

Optimize productivity & efficiency

through seamlessly integrated processes in production

Minimize time & effort

for the coordination of suppliers and technologies

Increase quality & consistency

through optimally harmonized processing steps

For over 60 years, GREIF-VELOX has been firmly established in the international markets of the chemical, food and petrochemical industries and is valued by customers and partners for its customized filling and packaging solutions, reliability and innovative strength.

Quote: Managing Director Sebastian Pohl

Became the market leader within just a few years

Our experience is reflected in a large number of projects, such as the increase in packaging efficiency at GoodMillsGroup, where we were able to effectively double production output, and the implementation of our ValvoDetect system at ICL Ladenburg, which led to a significant reduction in complaint and cleaning costs.

These and many other case studies demonstrate our ability to respond to a wide range of industry requirements and provide customized, effective solutions. If you would like to see specific examples of our work or gain a deeper insight into our bespoke installations, please contact the appropriate contact person.

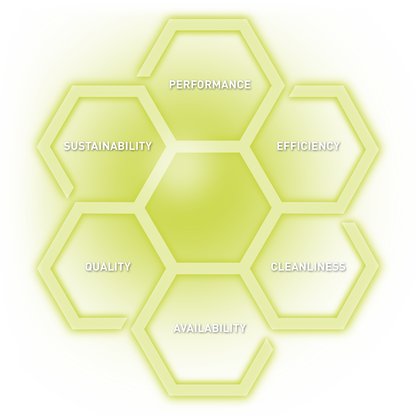

The 6 Key Success Drivers from GREIF-VELOX

For innovative production technology

Sustainability

Sustainability at GREIF-VELOX means a significant reduction in the CO₂ footprint through the use of energy-efficient and waste-minimizing technologies that not only protect the environment, but also reduce operating costs.

Quality

Quality at GREIF-VELOX means compliance with the highest industry standards and customer expectations through precise processing and control, which leads to increased customer satisfaction.

Performance

Performance reflects our commitment to delivering powerful and reliable systems that increase productivity and ensure consistently high output levels.

Availability

Availability underlines our commitment to maximum asset availability and minimal downtime, supported by proactive maintenance and rapid customer service, resulting in optimized uptime.

Efficiency

Efficiency is embodied by our filling solutions, which streamline production processes, minimize resource consumption and thus help reduce costs without compromising product quality.

Cleanliness

Cleanliness in our context means adhering to the strictest hygiene standards to ensure the safety and purity of products in chemical, petrochemical and food industries, minimizing the risk of contamination.

Increase production efficiency and production flexibility

Through advanced filling and packaging technology

as well as intelligent system design

GREIF-VELOX relies on innovative engineering solutions to maximize efficiency in the filling and packaging industry. By this we mean these specific functions and systems that are implemented in our machines to improve precision, speed and safety.

Automated control mechanisms

By using automated monitoring and control technologies, our systems ensure that every filling process takes place within the specified tolerances. This minimizes human errors and ensures consistently high product quality.

Integrated safety systems

Advanced security features protect both operators and product integrity. This includes containment solutions and airflow management that both protect employees from hazardous substances and prevent cross-contamination between different products.

Digital integration and data management

By integrating intelligent software and IoT technologies, our machines offer advanced analysis functions and real-time monitoring. This makes it possible to continuously optimize the production process and make informed decisions based on data.

Flexible and modular construction

Our systems are designed so that they can be easily adapted to different product types and packaging sizes. This enables quick switching between different products and increases the overall productivity of the system.

Dynamic dosing systems

Our systems are equipped with precise dosing systems that enable quick and precise filling. These systems dynamically adapt to different product characteristics and filling requirements, resulting in less product loss and higher efficiency.

GREIF-VELOX-System portfolio

Seamless integration into existing production processes

Filling lightweight materials: clean, efficient, sustainable

GREIF-VELOX revolutionizes your lightweight bagging of powders and granules

The GREIF-VELOX lightweight filling systems specialize in the bagging of fine, light powders and granules. They can easily be integrated into existing production lines or expanded into full-line systems. With the VeloVac we are setting new standards for the filling of carbon black by enabling dust-free bagging in a vacuum chamber and a maximum product compression of up to 400 percent, which significantly reduces storage and logistics costs.

Filling solids: efficient, specific, flexible

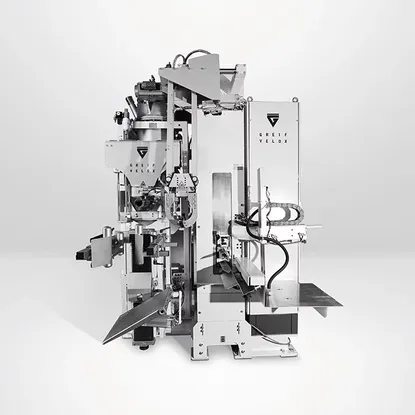

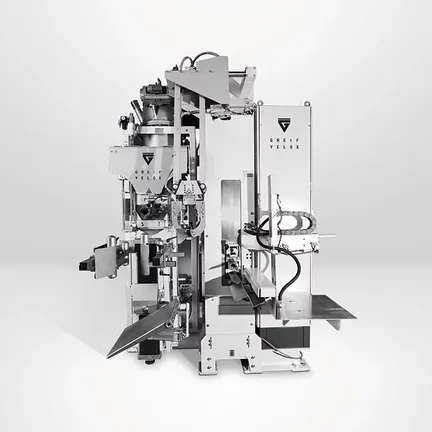

Innovative bag filling for fine and coarse-grained materials with GREIF-VELOX systems

GREIF-VELOX solids filling systems guarantee precise bag filling for fine and coarse-grained materials, realized through ultrasonic welding and the highest filling accuracy, which minimize product loss and increase operational efficiency. Our solid filling systems are ideal for the chemical and petrochemical sectors as well as the food industry. Integration into existing production lines is just as easy as development into a full-line system.

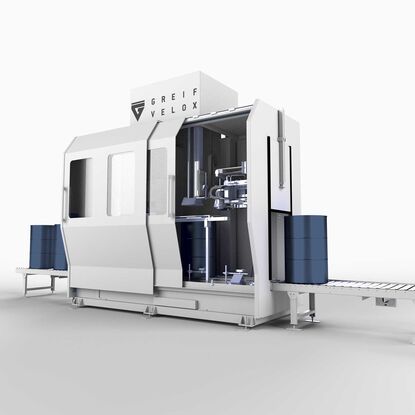

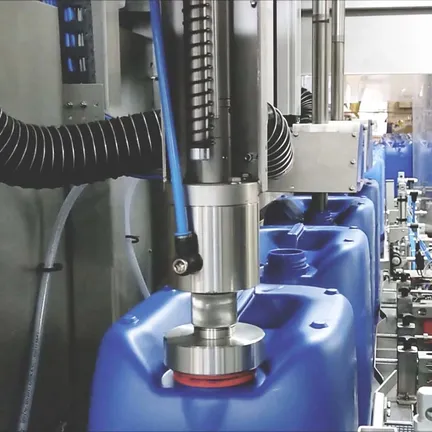

Filling liquids: precise, automatic, safe

GREIF-VELOX maximizes the productivity of your liquid filling processes

GREIF-VELOX liquid filling systems optimize productivity through precise, automatic and safe filling processes for liquids of different viscosities, from foaming to non-foaming in canisters, barrels and IBCs, complemented by automated functions such as labeling and capping for industries such as chemicals, petrochemicals and food. Seamless integration into existing production processes is just as uncomplicated as full-line development.

Palletizing & load securing

High-performance palletizing for perfect layer and stacking patterns

GREIF-VELOX palletizing robots are specifically designed for companies looking for flexible, quick-to-use and robust solutions to automate their final packaging processes. They are ideal for applications where reliability, high stacking quality and precise handling of a wide range of packaged goods are required, and offer a significant increase in palletizing speed and an improvement in working conditions by minimizing heavy manual work.

Case studies for increasing efficiency and flexibility with GREIF-VELOX systems

Through innovative engineering solutions for more precise, faster and safer systems

We demonstrate how GREIF-VELOX uses individually tailored filling systems and packaging systems to improve production speed, measurement accuracy and operational safety in specific production facilities worldwide. Our detailed case studies illustrate diverse success stories in the chemical, food and other sectors, supported by quantitative results and real improvements.

Chemical industry

Hydrogen peroxide filling system for Evonik

Our filling system at the chemical company Evonik led to an impressive increase in filling speed by 50 percent. Additionally, we significantly improved product safety by implementing advanced contamination control measures integrated into a highly automated hydrogen peroxide filling system, increasing not only efficiency but also workplace safety.

Food industry

Bagging system for GoodMills Germany

At the food producer GoodMills Germany, we were able to significantly increase packaging efficiency by 100 percent thanks to our systems. We also maximized the accuracy of the filling processes, doubling production output to up to 400 bags per hour, while at the same time minimizing cleaning effort and changeover times by using our gross pneumatic packer BVPV 4.40.

We offer you service every day.

we employ worldwide at GREIF-VELOX.

we have realized so far.

This is GREIF-VELOX: a pioneer of filling and packaging technology in 1,000 years of company history

EIR - Efficiency, innovation, reliability

are the cornerstones of our business philosophy

Reduction of operating costs

by reducing transport and logistics costs & saving cleaning and personnel costs

Optimization of production processes

by reducing downtimes, increasing production performance and data-supported process optimization

Improve security and compliance

by increasing employee and product safety

Innovation leadership in the filling and packaging industry

by integrating real-time data collection and Industry 4.0 concepts

Development of customer-specific solutions

through tailor-made adjustments based on specific customer needs, resulting in more efficient production processes

Promoting digital transformation

by using the latest digital tools and platforms for optimized and transparent production, increases productivity and reduces downtime

Maximum system availability

through robust design principles and continuous quality controls, resulting in lower failure rates and longer life cycles of the systems

Competent customer support

through rapid technical support & comprehensive maintenance programs, resulting in minimized downtime and optimized operations

Comprehensive security standards

through ongoing training and safety checks, ensures maximum safety for personnel and production

Knowledge: Transformative production strategies

Process optimization, Industry 4.0 and automation

How automation techniques help increase efficiency, reduce waste and ensure high product quality.

GREIF-VELOX explains the importance and challenges of Industry 4.0 and shows examples of implementation from industrial practice.

Basics, goals and methods of Lean Production process optimization. You will learn how companies can remain competitive through Lean Production.

How predictive maintenance minimizes unplanned downtimes, reduces costs and maximizes system availability - for future-proof production.

The cycle time measures the processing time of a production step and is crucial for process optimization. In addition, the differences to throughput time and cycle time as well as strategies for reduction.

Lead time describes the time span from the start of production to completion. Find out how it is calculated, what influencing factors there are and how companies can reduce lead time.

How time, cost and quality-related key figures in production reveal weak points and optimize processes - for greater efficiency.

Find out how to optimise production processes using lean methods, digital tools and the extended production triangle. Guide with expert knowledge.

By implementing lean methods as part of strategic lean management, GREIF-VELOX is realizing leaner battery production with the Velovac.

Total Productive Maintenance (TPM) increases production output by maximizing plant availability. Find out how TPM optimizes production processes, reduces losses and makes maintenance measures more efficient.

How manufacturing companies use Overall Equipment Effectiveness (OEE) to optimize their production performance. Use OEE to identify losses and improve processes.

The 5S method is a lean management approach to creating an organized, clean and standardized workplace. 5S increases efficiency, reduces waste and increases safety in production and the office.

How to reduce waste and increase efficiency in production plants using lean management principles and methods. Examples from production and assembly.

Our areas of exptertise

Your contact person will be happy to help you