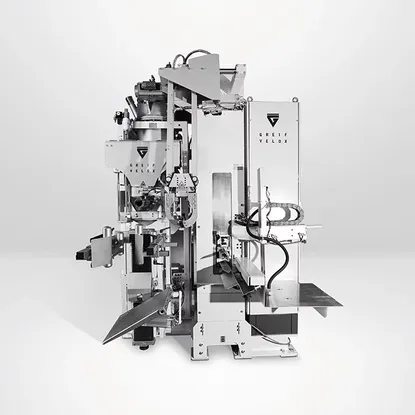

Product data of the BVT turbine packer

| Container | Valve bags made of paper, PE or PP fabric |

|---|---|

| Medium | powdery products and product mixtures |

| Grain sizes | from 30 µm to 3 mm |

| Industry | Chemistry, petrochemicals, food |

| Performance | up to 250 bags per hour |

The BVT turbine packer solves your filling challenges

Solved: Your filling challenges

Slow filling processes and low production capacities

High BVT filling rates increase the productivity and capacity of your production lines.

High product losses due to inaccurate weight controls

Precise integrated weighing systems reduce waste and save costs.

Frequent downtimes and constantly increasing maintenance costs

The BVT's robust design and easy maintenance access reduce downtime and maintenance effort.

Health and safety concerns due to dust generation

Low-dust technology improves working conditions and meets legal requirements.

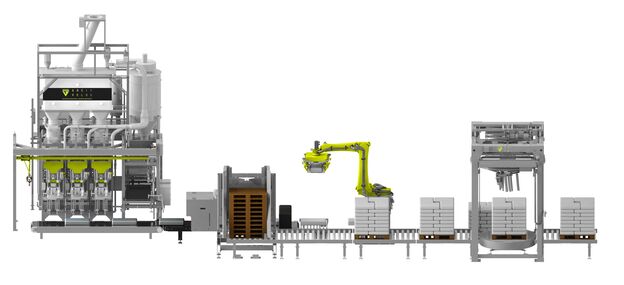

Compatible extensions

As part of a closed production system, our filling systems go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology. The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

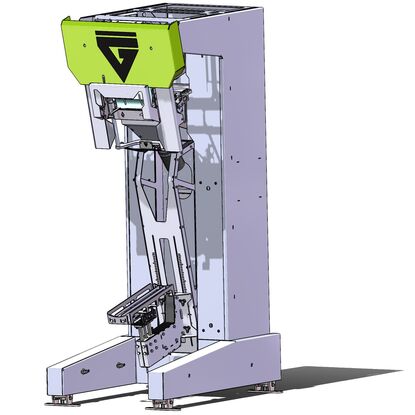

More GREIF-VELOX air packers