Filling lightweight materials:

clean, efficient, sustainable

VeloVac bagging system revolutionizes your powder and light material bagging

The main area of application is the bagging of light, powdery products such as carbon black with the possibility of implementing dust-free and efficient bagging processes. In particular, VeloVac offers solutions for big bag filling with special requirements for dust freedom and product compaction.

Maximum product compression of up to 400 percent reduces storage and logistics costs.

Dust-free bagging processes using a vacuum chamber protect employees and increase environmental friendliness.

Flexible system configuration allows adaptation to different room conditions.

Clean and precise bagging increases product quality.

Filling liquids:

precise, automatic, safe

Liquid filling systems from GREIF-VELOX maximize the productivity of your liquid filling processes

Greif-Velox offers solutions for filling liquids into canisters, drums and IBCs suitable for industries such as chemicals, petrochemicals and food. This includes the ability to efficiently fill liquids of varying viscosity.

Easily adaptable to different container types and material requirements.

Ensuring precise temperature settings for optimal liquid processing.

Use of stainless steel and plastic in GMP compliant solutions that adapt to specific material requirements.

Use of automatic labeling, sealing and valve coding reduces the number of personnel and ensures cleanliness and traceability.

non-foaming

foaming

Viscose fabrics

Filling solids:

efficient, specific, flexible

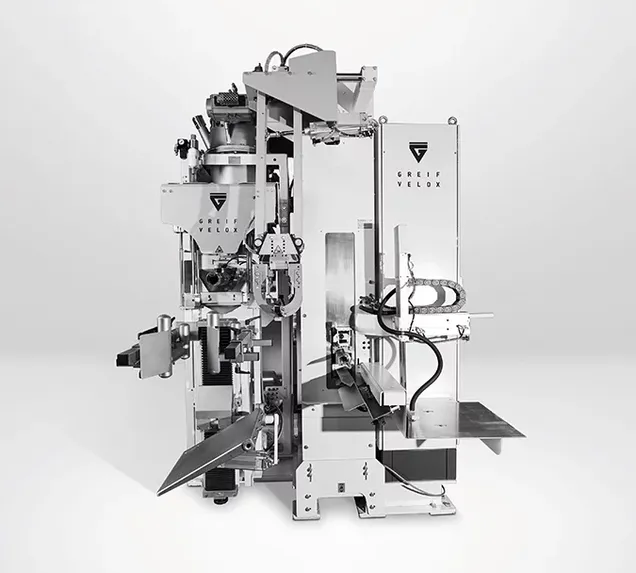

Innovative valve bag filling systems for fine and coarse-grained materials

GREIF-VELOX develops innovative bag filling technologies that are suitable for fine-grained and coarse-grained materials. Our systems ensure efficient and precise packaging, improving operational efficiency while reducing the need for manual labor.

Bagging products in a wide weight range (from 4kg to 40kg) for maximum flexibility.

10 times higher accuracy than OIML requirements, which reduces product usage and increases planning security.

Patented ultrasonic welding guarantees maximum safety and tear resistance.

Filling of powdery materials up to 3mm grain size at rapid speed.

Significant reduction in residual product leads to shorter cleaning times and thus increases in efficiency.

Fine flours:

< 200μm

Fine-grained semolina:

200μm - 800μm

Grist:

2mm - 4mm

Filling systems for drums

Fill drums precisely, automatically and safely

The GREIF-VELOX filling systems were specially developed for the efficient and safe filling of drums.

Our systems are designed for bung or clamping ring lid drums made of sheet steel or plastic and cover a wide range of liquids with different viscosities.

Optimize your filling process with our filling systems for drums in the chemical, petrochemical and food industries.

Filling systems for IBC

Fill IBC precisely, automatically and safely

Greif-Velox develops innovative filling solutions for filling liquids in intermediate bulk containers (IBCs) that are designed for maximum precision, automation and safety.

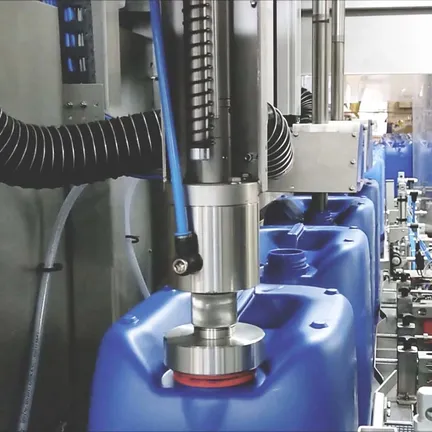

Filling systems for canisters

Fill canisters precisely, automatically and safely

At GREIF-VELOX, our filling systems for canisters combine advanced filling technologies with decades of experience in production technology to ensure automated, precise and safe filling.

Specially designed for canisters made of plastic or tinplate, our filling systems handle a variety of liquids - from water-like to viscous - and are used in various industries such as chemistry, petrochemicals and food.

Pallet filling systems for liquids

Flexible filling of various containers such as drums, IBCs or canisters

The pallet filling systems from GREIF-VELOX are a flexible and efficient solution for filling liquids into various containers such as drums, IBCs or canisters, which are placed directly on pallets.

These liquid filling systems make it possible to first place the empty containers on pallets and then fill them, which eliminates the need for separate palletizing technology for full containers.

Advantages of production automation with GREIF-VELOX filling systems

Success factors for the chemical, petrochemical and food industries

Clean

GREIF-VELOX filling systems use advanced cleaning systems that ensure constant cleanliness to prevent contamination.

Automatically

Fully automatic processes in the GREIF-VELOX systems reduce the need for manual intervention and thereby increase efficiency and safety.

Efficient

By automating and optimizing filling processes, Greif-Velox systems maximize production speed while reducing waste and operating costs.

Safe

Safety features are integrated into every GREIF-VELOX bottling line to protect both operators and products and ensure compliance with industry standards.

Sustainable

GREIF-VELOX integrates environmentally friendly technologies into its filling systems that minimize energy consumption and promote the reusability of resources.

Specific

GREIF-VELOX offers individually tailored solutions that are tailored precisely to the specific requirements and needs of customers.

Precise

The sophisticated control technology enables the GREIF-VELOX filling systems to fill products with exceptional accuracy and consistency.

Flexible

Modularity and adaptability allow different products and container sizes to be handled with minimal changeover times, simplifying switching between different production runs.

Case studies for

increasing efficiency and making production

more flexible with GREIF-VELOX systems

Chemical industry

Hydrogen peroxide filling system for Evonik

Our filling system at the chemical company Evonik led to an impressive increase in filling speed by 50 percent. Additionally, we significantly improved product safety by implementing advanced contamination control measures integrated into a highly automated hydrogen peroxide filling system, increasing not only efficiency but also workplace safety.

Food industry

Bagging system for GoodMills Germany

At the food producer GoodMills Germany, we were able to significantly increase packaging efficiency by 100 percent thanks to our systems. We also maximized the accuracy of the filling processes, doubling production output to up to 400 bags per hour, while at the same time minimizing cleaning effort and changeover times by using our gross pneumatic packer BVPV 4.40.

Integration of GREIF-VELOX filling systems into existing production environments

GREIF-VELOX filling systems are specifically designed for smooth integration into existing production lines, which enables efficient and problem-free integration into customers' existing processes.

The A-DOS-P1 Full Line for the chemical industry and the gross pneumatic packer BVPV 4.40 for the food industry are examples of the modular and scalable systems. This flexibility ensures easy adaptation to different production requirements and container sizes.

more case studies with Greif-Velox filling systemsHolistic system solutions

Complete systems instead of individual machines, which simplifies integration.

Modular design

Flexible adaptation and expansion of the systems to the existing production lines.

Scalability

Easy adaptation to changing production volumes and different container sizes.

Increased efficiency

Seamless integration increases operational reliability and minimizes downtimes.

One contact person

for your entire project.

For over 60 years, GREIF-VELOX has been firmly established in the international markets of the chemical, food and petrochemical industries and is valued by customers and partners for its customized filling and packaging solutions, reliability and innovative strength.

Quote: Managing Director Sebastian Pohl

Became the market leader within just a few years

Our experience is reflected in a large number of projects, such as the increase in packaging efficiency at GoodMillsGroup, where we were able to effectively double production output, and the implementation of our ValvoDetect system at ICL Ladenburg, which led to a significant reduction in complaint and cleaning costs.

These and many other case studies demonstrate our ability to respond to a wide range of industry requirements and provide customized, effective solutions. If you would like to see specific examples of our work or gain a deeper insight into our bespoke installations, please contact the appropriate contact person.