Filling systems

GREIF-VELOX specializes in precise filling solutions tailored to the individual needs of specific industries such as food processing and chemicals.

By using our specialized filling systems, such as air packers for powdery materials, vacuum fillers for light, difficult-to-flow materials and liquid filling systems for different viscosities, we optimize your production processes and increase throughput rates.

Each filling system is adapted to the production conditions and production goals of our customers to ensure maximum efficiency through the highest system performance.

further information about filling systemsManageable substances

Liquids of varying viscosity levels, from water to thicker oils and syrups.

Coarse-grained materials and granules such as chemicals, waxes, titanium dioxide and phosphates as well as cocoa, starch and sugar.

Fine-grained powders and lightweight substances such as carbon black, silica, color pigments and pesticides.

Technological advantages

Reduced product waste and increased cost efficiency through precision filling.

Advanced weighing and measuring systems enable precise dosages.

Fast product and format changes thanks to modern control technology.

Allows flexible production and minimizes changeover times.

Increase production capacity through user-friendly design and maintenance.

Simplified operation and maintenance reduces downtimes.

Longevity and reliability thanks to first-class materials.

Utilizing stainless steel and specialty alloy components known for their corrosion resistance, strength under varying operating conditions and long-term durability.

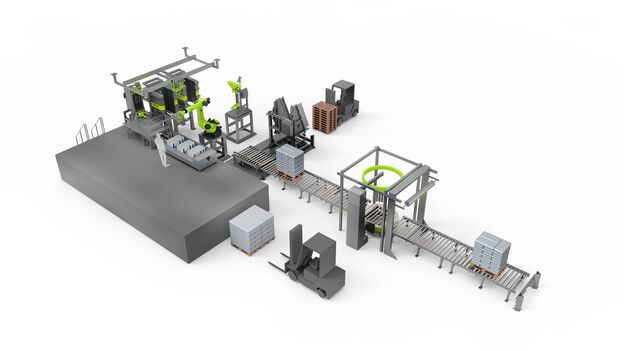

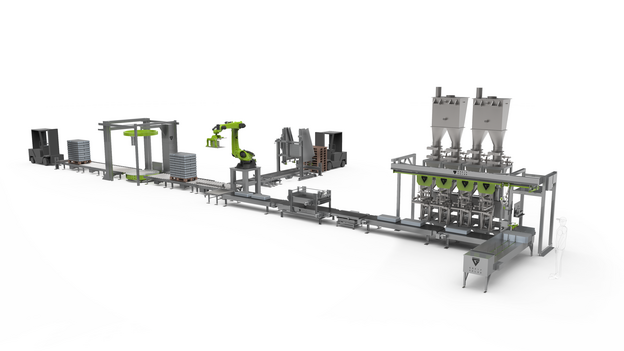

Palletizing robot

GREIF-VELOX Greif-Velox improves efficiency throughout the entire production chain for industries such as food and chemicals with advanced palletizing robots. These robots provide precise and fast palletizing and help optimize bag attachment, bag handling and final packaging.

The adaptability of our robots allows us to handle a wide variety of product shapes and packaging types, allowing a flexible response to different production requirements.

The configuration of each system is tailor-made according to the individual requirements of the customers, which optimizes production processes and improves working conditions.

further information about palletizing robots

Technological advantages

Increased production speed and accuracy.

Use of innovative gripping systems and advanced motion control techniques for fast and accurate palletizing.

Flexibility and adaptability.

Modular system configuration enables easy adjustments to new product types and packaging formats.

Improving work safety and ergonomics.

Automation reduces manual handling processes, which lowers the risk of injury. You can also counter the shortage of skilled workers.

Longevity and reduced maintenance.

The robust construction and the use of high-quality materials ensure a longer service life of the systems and reduce maintenance costs.