Perfectly coordinated system components for bagging carbon black

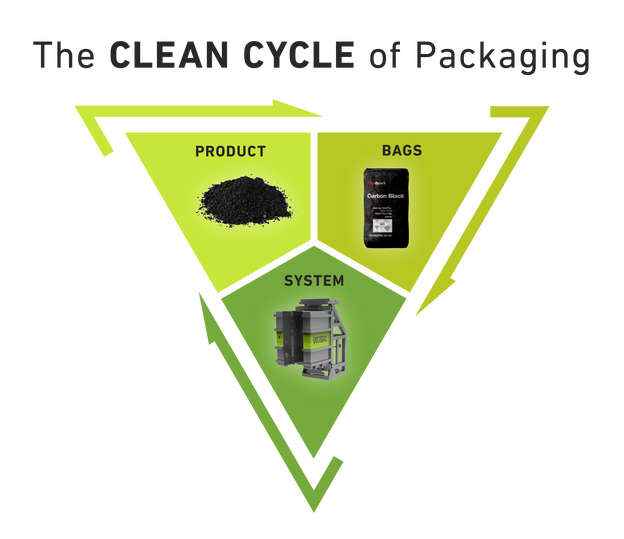

The “Clean Cycle of Packaging”

Product: Carbon Black is filled in optimized paper bags that offer efficient bagging and optimal product protection.

Packaging: Collaboration with dy-pack to develop paper bags that meet the requirements of the carbon black and the machine.

System: The use of VeloVac technology creates a closed system that avoids contamination and maintains bag quality.

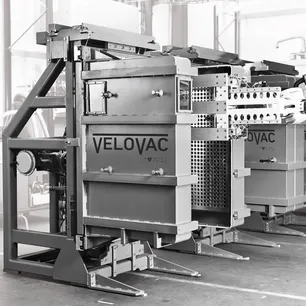

VeloVac vacuum packer: Revolution in the bagging of carbon black

The VeloVac was developed specifically for the challenges of carbon black bagging. By using a completely closed vacuum chamber, the fine powder is packaged safely and without dust emissions.

Advantages of carbon black bagging with the VeloVac

Reduced cleaning costs: Completely closed system prevents dust emissions

Health protection: No exposure of employees to fine carbon black

Optimized logistics: Fourfold compaction of the material saves costs and space during transport and storage

Higher product purity: Important requirement for areas of application such as battery production

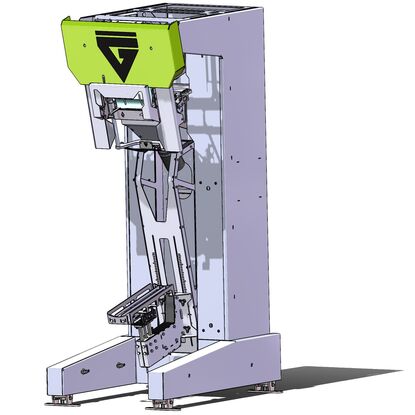

Carbon Black Bagging Options

Automated handling: Robot systems for handling the filled bags

Adjustable configuration: Flexible adaptation of the system to specific customer needs and production volumes

Advanced security features: Integrated monitoring systems to ensure system and production process security

Compatible features

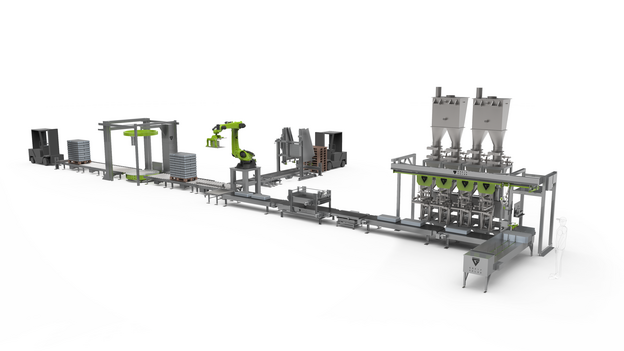

Interactive 3D animation of a VeloVac full-line system

Experience and explore in 3D

It's worth the wait: After the 3D animation is loaded, you can use it with the mouse pointer and mouse wheel (zoom). Don't miss to click on the -buttons.

Holistic system solutions through full-line filling systems

Our filling systems are part of a comprehensive production system that can be seamlessly integrated into existing lines. GREIF-VELOX ensures that each system is optimally tailored to the specific requirements of customers in order to maximize productivity and reduce operating costs.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.