Efficient starch filling systems

Choosing the right system for bagging starch depends on your individual production requirements. While our VELOVAC vacuum packer is ideal for light, powdery substances such as starch and impresses with its compact compaction and outstanding dust control, the BVP/BVPV pneumatic packer offers maximum flexibility and performance for the calibrated filling and processing of larger production volumes.

VELOVAC therefore enables a higher packing density, which not only reduces logistics costs, but also ensures a clean working environment. In contrast, the BVP/BVPV scores with its fast changeover and impressive filling capacity of up to 400 bags per hour - ideal for companies with high throughput requirements and varying bag sizes.

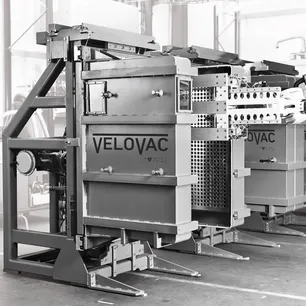

VELOVAC

The VELOVAC is the ideal solution for bagging starch in the food industry. With its innovative vacuum technology, the VELOVAC enables an extremely high packing density while minimising dust emissions. This not only ensures a clean working environment, but also the best possible protection for the end product.

Thanks to its flexible customisation options, the VELOVAC is ideal for both high-volume production and smaller batches. The integrated application-specific suction system ensures maximum process reliability, while the precise dosing technology fulfils the requirements for calibrated filling. The VELOVAC thus combines efficiency, precision and cleanliness in one system.

Core features

Highest packing density for optimised logistics and storage

Minimisation of dust emissions thanks to integrated extraction technology

Flexible application options for different packaging sizes and production quantities

Special features

Vacuum technology reduces air content in the bag and increases the stability of the packaging

Reduction in material consumption and CO₂ emissions thanks to compact packaging

Simple operation and short changeover times thanks to user-friendly automation

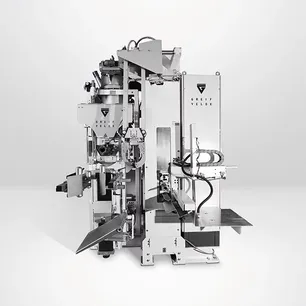

Gross pneumatic packer BVP/BVPV

The BVP/BVPV pneumatic packers are specially designed for the requirements of starch bagging and offer maximum efficiency and flexibility. With their robust pneumatic technology, they guarantee accurate filling and constant output - even with high throughput requirements. These systems are perfect for use in the food industry, where precision and process reliability are top priorities.

Thanks to their high changeover capability, the BVP/BVPV packers can be quickly adapted to different bag sizes and packaging requirements. They are ideal for production lines that require high flexibility with changing batches, while offering an impressive output of up to 400 bags per hour. The optimised control system ensures that every filling is efficient and precise.

Core features

Accurate filling for maximum precision and minimum product loss

High filling speed with up to 400 bags per hour

Flexible adaptation to different bag sizes and product specifications

Special features

Perfectly suited for fine powders such as starch thanks to optimised pneumatic technology

Minimal maintenance thanks to durable and robust design

User-friendly control system for simple operation and fast changeover times

Systems for maximum precision, cleanliness and automation

ValvoMat - precision and automation in bag filling

The ValvoMat is a state-of-the-art extension for our gross pneumatic and vacuum packers. It has been specially developed for automatic bag opening and positioning. The ValvoMat automates the entire filling process by positioning the bags precisely at the filling spouts and sealing them reliably. This reduces manual labour and significantly increases productivity.

The combination of precise bag positioning and automatic closing makes the ValvoMat the ideal addition to production lines that require maximum accuracy and cleanliness with minimum downtime.

ValvoMat in detail

SafeDyVac - safety and cleanliness through dust control

The SafeDyVac system was developed to significantly reduce dust emissions during filling while ensuring a clean working environment. It works with an application-specific extraction system that ensures both employee safety and product cleanliness.

This system is particularly valuable in starch bagging, as it counteracts the typical dust problems associated with powdered products.

Learn more about the SafeDyVac system

Holistic system solutions with full-line filling systems

As part of a closed production system, our filling systems for food go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to fulfil complex requirements from container preparation and filling through to post-processing and storage, making us an integrated system provider in production technology.

The focus is on customisation to ensure optimum integration into the respective operating processes.

Food industry

Bagging system for GoodMills Germany

At the food producer GoodMills Germany, we were able to significantly increase packaging efficiency by 100 percent thanks to our systems. We also maximized the accuracy of the filling processes, doubling production output to up to 400 bags per hour, while at the same time minimizing cleaning effort and changeover times by using our gross pneumatic packer BVPV 4.40.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.