GREIF-VELOX-Abfüllanlagen

Smarter Packaging. Smarter Business.

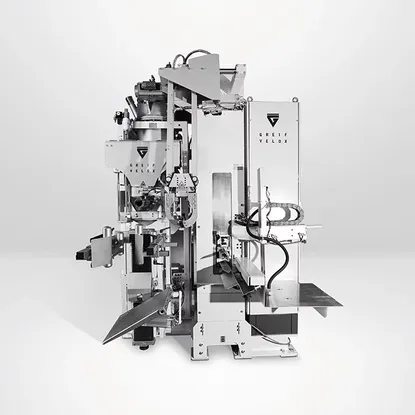

Vakuumpacker

Luftpacker

FIBC-Abfüllanlagen

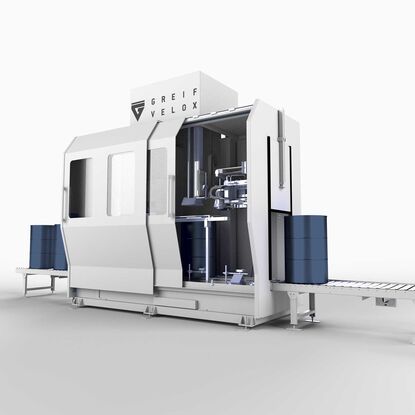

Fass-Abfüllanlagen

IBC-Abfüllanlagen

Kanister-Abfüllanlagen

Paletten-Abfüllanlagen

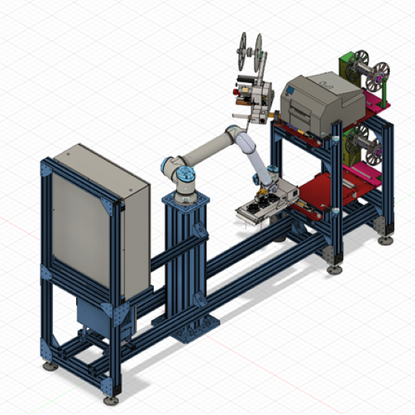

Palettierung & Ladungssicherung