Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each granule filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to cleanliness, efficiency and sustainability in order to protect fabric quality and ensure maximum safety for our customers despite the highest production efficiency.

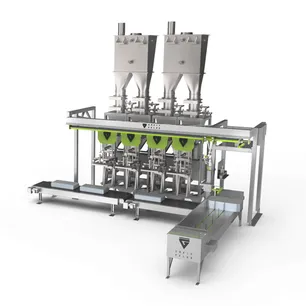

Specific filling requirements require individual system solutions

GREIF-VELOX offers tailor-made filling solutions that are specifically tailored to the requirements of the food, chemical and petrochemical industries. The systems effectively process everything from the finest pigments to coarse granules.

Precision in every grain:

Flexible adaptation to different container sizes and types.

Automatic systems for optimal handling and process efficiency.

Purity and safety:

Dust-free technologies to ensure product quality.

Robust system designs that meet strict industrial safety standards.

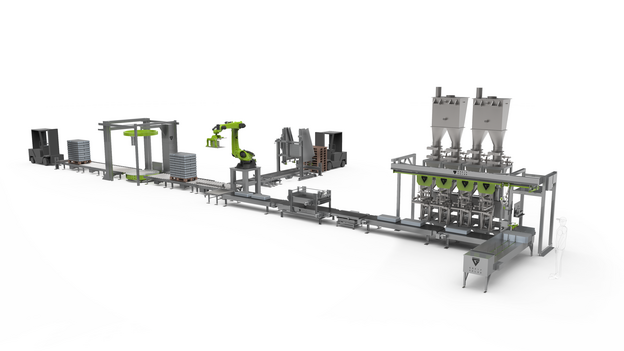

Holistic system solutions through full-line filling systems

Our filling systems are part of a comprehensive production system that can be seamlessly integrated into existing lines. GREIF-VELOX ensures that each system is optimally tailored to the specific requirements of customers in order to maximize productivity and reduce operating costs.

(Dust-free) powder filling systems for different grain sizes

Different grain sizes, different filling solutions: according to your needs.

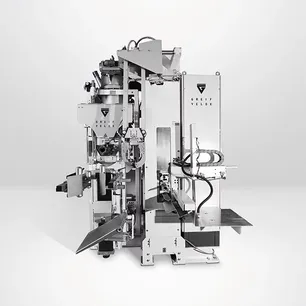

GROSS PNEUMATIC PACKER BVP

With the gross pneumatic packer BVP, GREIF-VELOX sets new standards in the bagging of powdery and fine-grained products.

This system offers calibration-accurate bagging and is ideal for handling various grain sizes, from very fine to medium-sized, achieving a high throughput of up to 400 bags per hour.

Core features

High bagging performance with up to 400 bags per hour

Flexibility in filling different grain sizes and product types

Calibrated filling that enables product savings through accuracy

Besonderheiten

Specialized in challenging industries such as chemicals, petrochemicals and food

Ability to empty with almost no residue for efficient product changes

Hygienic design and easy cleaning, optimized for quick product changes

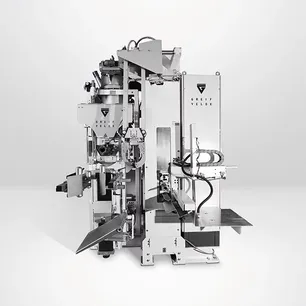

Gross pneumatic packer BVPV

GREIF-VELOX revolutionizes the bagging of powders and granules with the gross pneumatic packer BVPV.

This high-speed system enables efficient bagging of up to 800 bags per hour and is ideal for a wide range of products, from fine powders to coarser granules.

Core features

Extremely high filling speed with precise dosage

Adaptable to a variety of products and container sizes

Optimized for low cleaning and downtimes thanks to high residual emptying capacity

Special features

Versatile in industries such as chemicals, petrochemicals and food

Minimization of cleaning times thanks to the innovative bowl shape

Simple operation and quick product changes supported by storable machine parameters

Gross turbine packer BVT

With the gross turbine packer BVT, GREIF-VELOX is setting new standards in the quick and precise bagging of products where no dust is expected to be generated.

This system is particularly suitable for mono products and uses innovative technologies to optimize bagging efficiency.

Core features

Optimal filling through innovative product ventilation

Low cleaning effort thanks to the closed dosing system

Fast and efficient product changes thanks to storable machine parameters

Special features

Excellent price-performance ratio

Versatile for different products and grain sizes

Available with accessories such as ultrasonic welding and fully automatic attachment

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.