News at GREIF-VELOX

Valuable information about current trends and developments for companies, engineers, technicians and partners who want to stay up to date on topics related to filling systems and packaging machines.

Discover our collection of specialist articles and industry news that provide a good insight into our expertise and focus areas.

Faster service, less downtime: The Greif-Velox spare parts portal enables digital, intuitive ordering directly from the machine view.

Detecting and Removing Faulty Bags with ValvoDetect.

Maximum efficiency, full cost control, and reliable supply: With our new PaaS model, we are simplifying industrial powder bagging like never before.

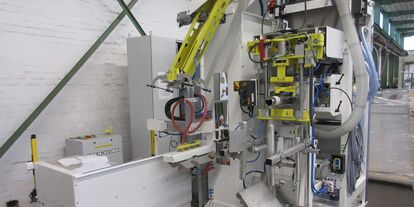

Efficient filling of micronized waxes with our gross pneumatic packer.

When high-tech materials meet demanding packaging requirements, precision is key. That’s exactly the challenge Birla Carbon presented to us.

Working together for smart packaging solutions: Our partnership with Trans Automation Technologies marks a significant step in expanding our presence in the U.S. market.

130 guests, impressive technology, and strong partnerships — that was our in-house exhibition, GREIF-VELOX CONNECT, on May 13, 2025.

The R-DOS Essential from GREIF-VELOX is a compact, semi-automatic filling system for flexible, economical and safe liquid filling.

With a Christmas raffle in December 2024, the employees of GREIF-VELOX together with the management collected 1,750 euros for Tafel Lübeck.

In view of the growing demand for efficient packaging solutions in the Gulf region, GREIF-VELOX has entered into a strategic partnership with Packme Mena FZ LLC.

With the VeloFlexLabeler, GREIF-VELOX introduces an innovative, fully automated solution that meets the highest demands for precision, flexibility, and safety with absolute reliability.

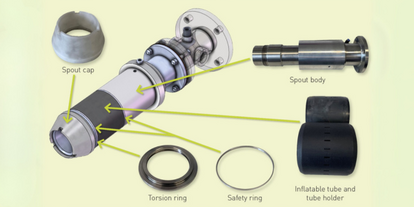

Achieve up to 125,000 cycles with GREIF-VELOX’s innovative inflatable tube seal. Reduce downtime, cut costs, and streamline replacements by 75%. Boost productivity today!