Filling solutions from GREIF-VELOX the food industry

Process-reliable filling of food.

Filling of light materials such as food powder

Example substances: baking aids, ready-made baking mixes, gluten, cocoa, bran, granulated sugar, powdered sugar, flour (wheat, rye, barley), milk powder, wholemeal meal, starch (potato, wheat, corn, peas)

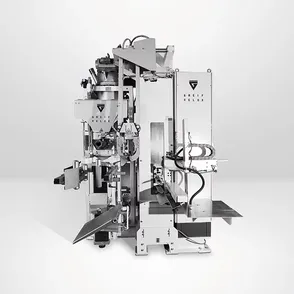

VELOVAC & VELOVAC XL

These vacuum packaging systems are specifically designed for light and fine powder materials. By using vacuum technology, these systems enable a significant reduction in packaging volume, resulting in optimized transport and storage costs.

The VELOVAC series is particularly suitable for high-value, easily contaminated materials by providing a dust-free and safe packaging environment.

Filling of solids such as food granules

Example substances: Ready-made baking mixes, rice, oat flakes, salt, starch products, tea mixtures, bran, wholemeal meal, wheat germ, granulated sugar, powdered sugar

BVP & BVPV (air packer)

These air packing systems are ideal for filling a wide range of solids for the food industry. They offer high dosing accuracy and are able to process products with different bulk densities and properties.

Applications range from oatmeal to rice, while ensuring high productivity and minimal product waste.

VeloPack

These robotic palletizing solutions are designed for end-of-line packaging handling of solid materials. VeloPack automates the palletizing process, increasing efficiency, reducing labor costs and minimizing the risk of injuries from manual lifting.

The VeloPack can be used flexibly for a variety of products and packaging types.

Filling of food liquids

Example substances: flavors, fragrances, enzymes, vinegar, fats, fatty acids, liquid spices, fruit juice, drinks, glucose, glycerin, cocoa mass and cocoa butter, ketchup, concentrates, lecithin, mayonnaise, lactic acid, mustard, cooking oil, vitamins

R-Dos

This precision dosing system was developed for the precise filling of liquid and pasty substances.

The filling line offers a customizable solution for different viscosities and product properties, ensuring consistent product quality and supporting a clean and safe working environment.

K-DOS & K-DOS-A

These (semi-)automatic filling systems are designed for precise filling into drums.

The filling systems offer a practical solution for smaller production volumes, combining adaptability with ease of use - ideal for production lines with a wider range of viscosities - from aqueous to very thick liquids.

A-DOS-C

The automatic and semi-automatic filling systems type A-DOS-C are an efficient and flexible solution for filling liquids in IBCs. They are ideal for a variety of industries, including chemical and food, and can handle liquids of varying viscosity.

These systems are particularly safe as they include functions such as the extraction of displaced gases and can be integrated into existing production lines or used as a standalone full-line system.

Food industry

Bagging system for GoodMills Germany

At the food producer GoodMills Germany, we were able to significantly increase packaging efficiency by 100 percent thanks to our systems. We also maximized the accuracy of the filling processes, doubling production output to up to 400 bags per hour, while at the same time minimizing cleaning effort and changeover times by using our gross pneumatic packer BVPV 4.40.

Holistic system solutions

through full-line filling systems

As part of a closed production system, our chemical filling systems go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology.

The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each liquid filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Maintenance service & retrofitting

Installation & commissioning

Professional installation and commissioning of filling systems to ensure optimum function and efficiency right from the start.

Spare parts (E-parts)

Provision and delivery of spare parts to facilitate maintenance and repairs of bottling plants and minimize downtime.

VPN service

Setting up a VPN service for fast and secure remote access and diagnostics, reducing time and costs for on-site service calls.

Maintenance service

Comprehensive maintenance services to ensure the longevity and efficiency of the filling systems and to avoid unplanned downtimes.

RetroFit

Retrofit solutions to modernize and increase the efficiency of existing systems, improving performance and extending the life of the systems.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.