Filling systems

GREIF-VELOX offers specialized solutions for the petrochemical industry, including the fully automatic A-DOS-P for flexible and efficient pallet filling, the K-DOS-A for filling processes of various container sizes and the R-DOS for the precise handling of foaming products.

These systems are specifically tailored to the requirements of petrochemicals such as accuracy, reliability and product safety and ensure maximum efficiency and quality assurance in production.

Overview: Filling solutions from GREIF-VELOX for petrochemical substances

Security &

control systems

Safety is a top priority in the petrochemical industry. GREIF-VELOX supports this with innovative solutions such as the AspirationShield for dust control and the ValvoDetect for the detection and sorting of defective packaging, which makes the working environment safer and ensures product quality.

Overview: Safety systems from GREIF-VELOX for petrochemical substances

Maintenance service & retrofitting

The GREIF-VELOX ValvoCare prevents contamination of filled bags and pallets by the product remaining behind the welding in the valve protrusion and thus enables a guaranteed clean bagging and palletizing result.

RetroFit solutions also enable the modernization and increase in efficiency of existing systems, which leads to an extension of the service life and a reduction in downtime.

Overview: Services from GREIF-VELOX for petrochemical filling systemsFilling of petrochemical solids

Example materials: Epoxy resins, fatty alcohols, naphthalene, paraffin, PE granules (LDPE, LLDPE, HDPE), PP granules

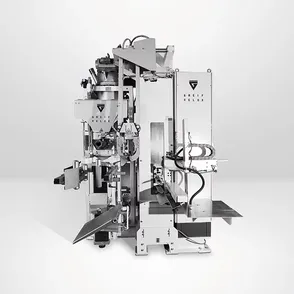

BVP & BVPV (air packer)

These air packer systems are ideal for filling a wide range of petrochemical solids. They offer high dosing accuracy and are able to process products with different bulk densities and properties.

Applications are possible for a wide range of petrochemical granules, while ensuring high productivity and minimal product waste.

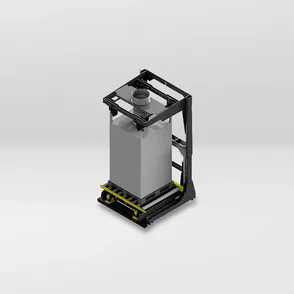

FIBC filling system

The FIBC filling system is specifically designed for handling and filling liquids into flexible intermediate bulk containers (FIBCs). This system offers a high level of flexibility and adaptability for a wide range of viscosities, from water-like to highly viscous liquids. Thanks to its semi-automatic operation, the FIBC filling system enables efficient and precise filling, making it particularly suitable for use in petrochemicals, where high demands are placed on cleanliness and accuracy.

With options such as automatic inerting and filling as well as the possibility of integration into customer control systems, this filling system supports optimal integration into existing production lines and contributes to compliance with safety standards, especially in potentially explosive areas.

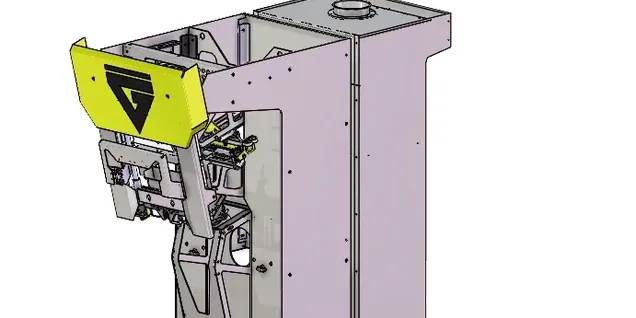

Velostar

The Velostar is a specialized, enclosed filling system that is ideal for the precise bagging of petrochemical materials such as powders, granules, pellets and product mixtures. With the ability to process materials from 50 µm up to 12 mm grain size, this facility offers exceptional flexibility and efficiency for the petrochemical industry.

The Velostar achieves an impressive filling speed of up to 350 bags per hour, making it an optimal solution for high-performance production environments. The enclosed design minimizes dust generation and contamination risks, which is particularly important when handling sensitive or dangerous petrochemical substances.

Filling petrochemical liquids

Example materials: Additives, dispersions, gear oils, hydraulic oils, cooling lubricants, engine oils, polyesters, lubricating greases, lubricating oils, silicone oils, technical oils, transformer oils, heat transfer oils, white oils / white greases

A-DOS-P1 & R-DOS

These precision dosing systems have been developed for the precise filling of liquid and pasty petrochemicals.

They provide a customizable solution for different viscosities and petrochemical properties, ensuring consistent product quality and supporting a clean and safe working environment.

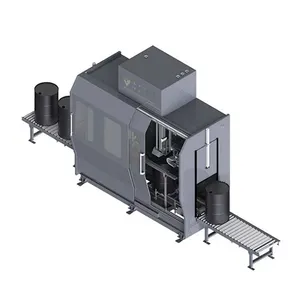

A-DOS-FS, A-DOS-K

These filling systems are designed for canisters and drums and offer solutions for filling liquids while taking into account safety, cleaning and efficiency standards.

They are particularly suitable for the petrochemical industry, where they are equipped with features such as explosion protection and material compatibility and are characterized by their high level of automation.

Efficient and flexible filling solutions

Security and control systems

ValvoDetect

Recognize packaging faults

ValvoDetect is a state-of-the-art detector for packaging inspection and quality assurance.

The system identifies and sorts out defective packaging before it reaches the end of the production line. ValvoDetect is particularly useful for detecting leaks, inadequate seals or other defects that could compromise the safety and quality of the final product. Using ValvoDetect results in higher product quality, reduced waste and increased end-user trust in your brand.

AspirationShield

Dust Control & Extraction

The AspirationShield is an advanced dust control and extraction system.

It is designed to minimize dust generation during the filling process. This system is particularly important for handling fine powders and substances that can easily cause dust explosions or health concerns. By effectively controlling dust, AspirationShield improves the working environment and reduces the risk of cross-contamination. It is ideal for companies that need to maintain strict cleanliness and safety standards in their production lines.

ValvoMat

Smooth material flow

The ValvoMat from GREIF-VELOX optimizes the handling of bags within chemical production lines.

This system is ideal for placing and opening bags, ensuring precise and controlled feeding of chemical substances in production processes. Thanks to the automated bag attachment process, the ValvoMat minimizes the risk of contamination while increasing safety and efficiency.

Holistic system solutions

through full-line filling systems

As part of a closed production system, our chemical filling systems go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology.

The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each liquid filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Maintenance service & retrofitting

Installation & commissioning

Professional installation and commissioning of filling systems to ensure optimum function and efficiency right from the start.

Spare parts (E-parts)

Provision and delivery of spare parts to facilitate maintenance and repairs of bottling plants and minimize downtime.

VPN service

Setting up a VPN service for fast and secure remote access and diagnostics, reducing time and costs for on-site service calls.

Maintenance service

Comprehensive maintenance services to ensure the longevity and efficiency of the filling systems and to avoid unplanned downtimes.

RetroFit

Retrofit solutions to modernize and increase the efficiency of existing systems, improving performance and extending the life of the systems.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.