Maintenance and remote service

Benefit from our comprehensive maintenance contract for GREIF-VELOX systems: regular maintenance intervals, proactive inspection and replacement of wear parts, and fast and efficient problem solving through secure remote connections. Minimize downtime, increase system performance and save costs.

Minimize downtime

Increasing plant performance

Cost savings

Safety

System Modernizations

GREIF-VELOX implements system modernizations that increase the efficiency of your existing production systems.

We ensure the long-term availability of spare parts and enable upgrades for outdated components. Our modernization services include ergonomic workplace improvements or even the integration of systems into existing production lines.

Conversion kits for obsolete components

Integration of modern machine technologies

Adaptation to common ERP systems

Specially tailored solutions

Over ten years of consistent spare parts supply security

Troubleshooting

We will provide you with effective troubleshooting for your systems to ensure their constant availability.

The service includes a help desk for immediate support requests, dedicated remote support teams and the ability to resolve 95 percent of incidents digitally via teleservice and video communication. If necessary, technical staff can be mobilized within a very short time.

Helpdesk for direct support

Remote support via modem, Ethernet and VPN

Rapid mobilization of technical staff

Average response time under 60 minutes

Spare parts service

We maintain a comprehensive in-house spare parts service that ensures the availability and longevity of your systems.

This service provides quick access to original spare and wear parts, includes an express delivery service and specialized support to minimize your production downtime.

Direct helpdesk for immediate support

Express delivery service for quick supply of spare parts

High quality OEM replacement and wear parts

Individually tailored spare parts packages

Maintenance / Repair

Our customer service includes comprehensive maintenance and repair services so that your systems run uninterrupted and trouble-free.

Regular inspections identify wear points at an early stage, while maintenance operations with OEM spare parts ensure the longevity of your systems. We also train your employees in individually tailored learning units to ensure the smooth operation of your systems independently within your production facility.

Regular inspections

Installation of OEM spare parts

System tests and calibrations

Needs-based employee training

VeloGuard wear & tear self-test solutions

Minimize downtime by monitoring wear your devices.

With the VeloGuard self-test solutions from GREIF-VELOX, your system gains added security through continuous automatic checks for the most common causes of sytem failures.

Elimination of lengthy troubleshooting by your technical departments

Secure production times without unplanned downtime

Improved ability to schedule downtimes for component replacement

DireDirect wear & tear notifications to the system's HMI

Retrofit:

An investment that pays for itself.

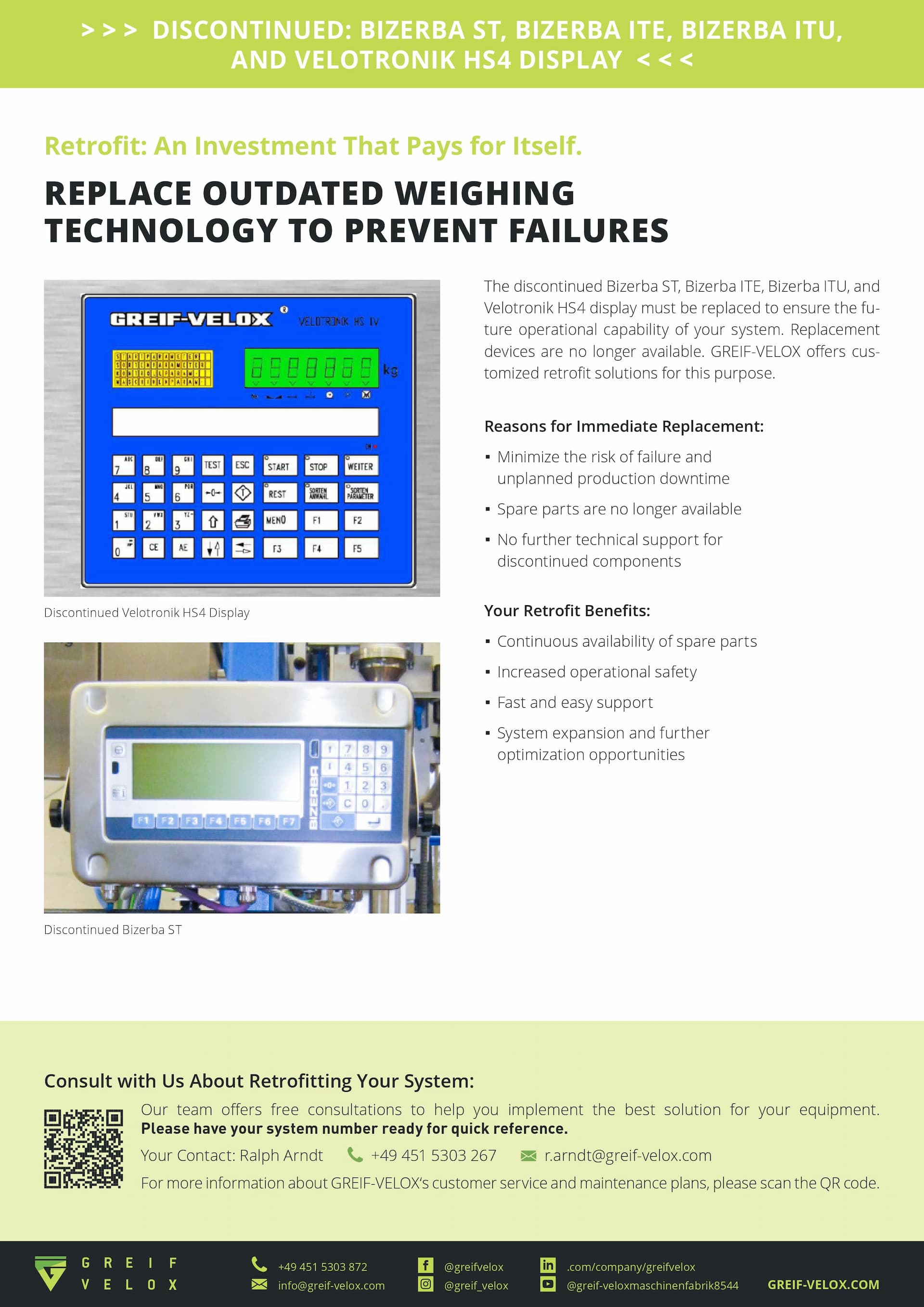

Replace outdated weighing technology to prevent failures

download PDF

Wear & tear monitoring devices

download PDF

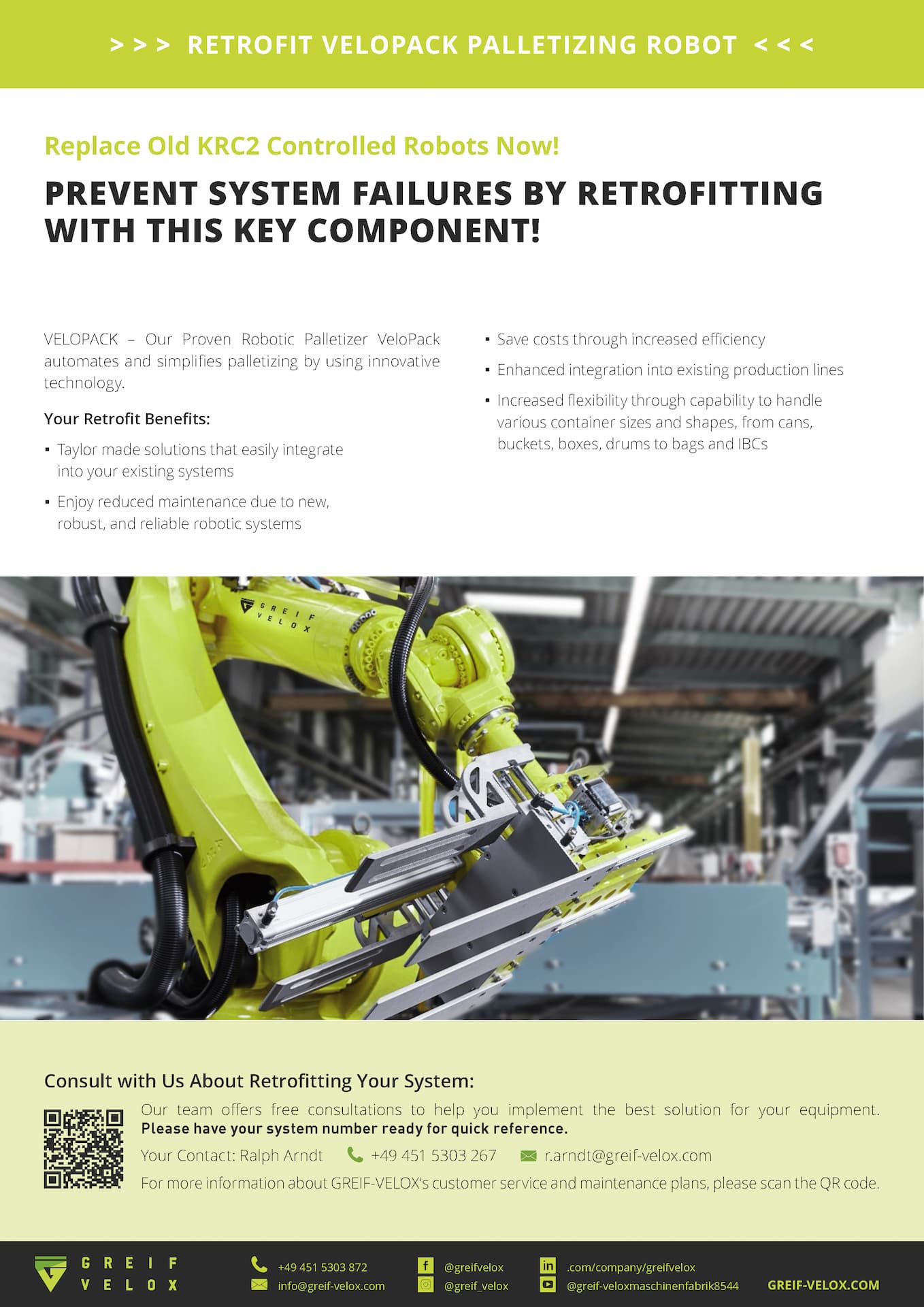

Prevent system failures by retrofitting with this key component

download PDF

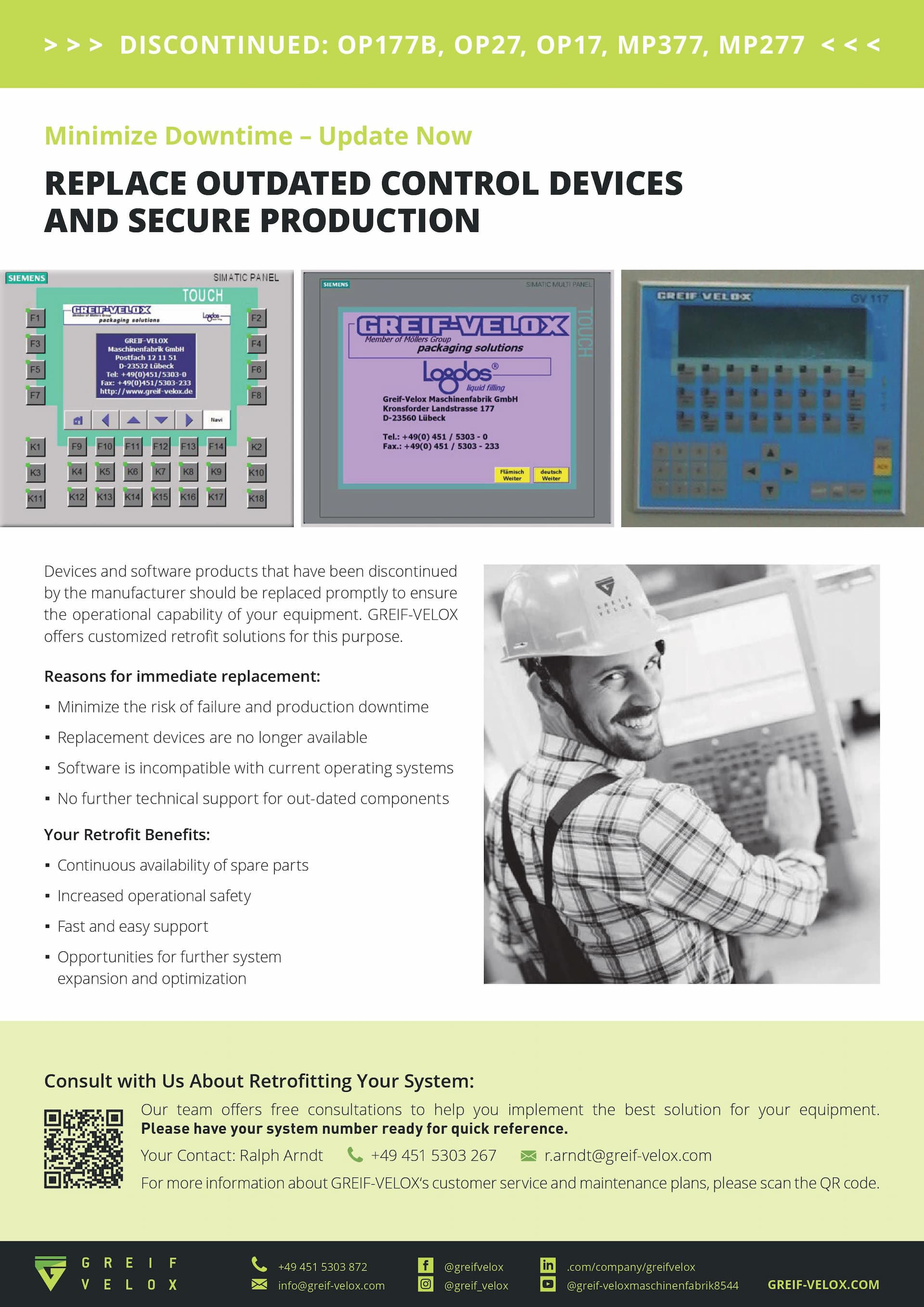

Replace outdated control devices and secure production

download PDF

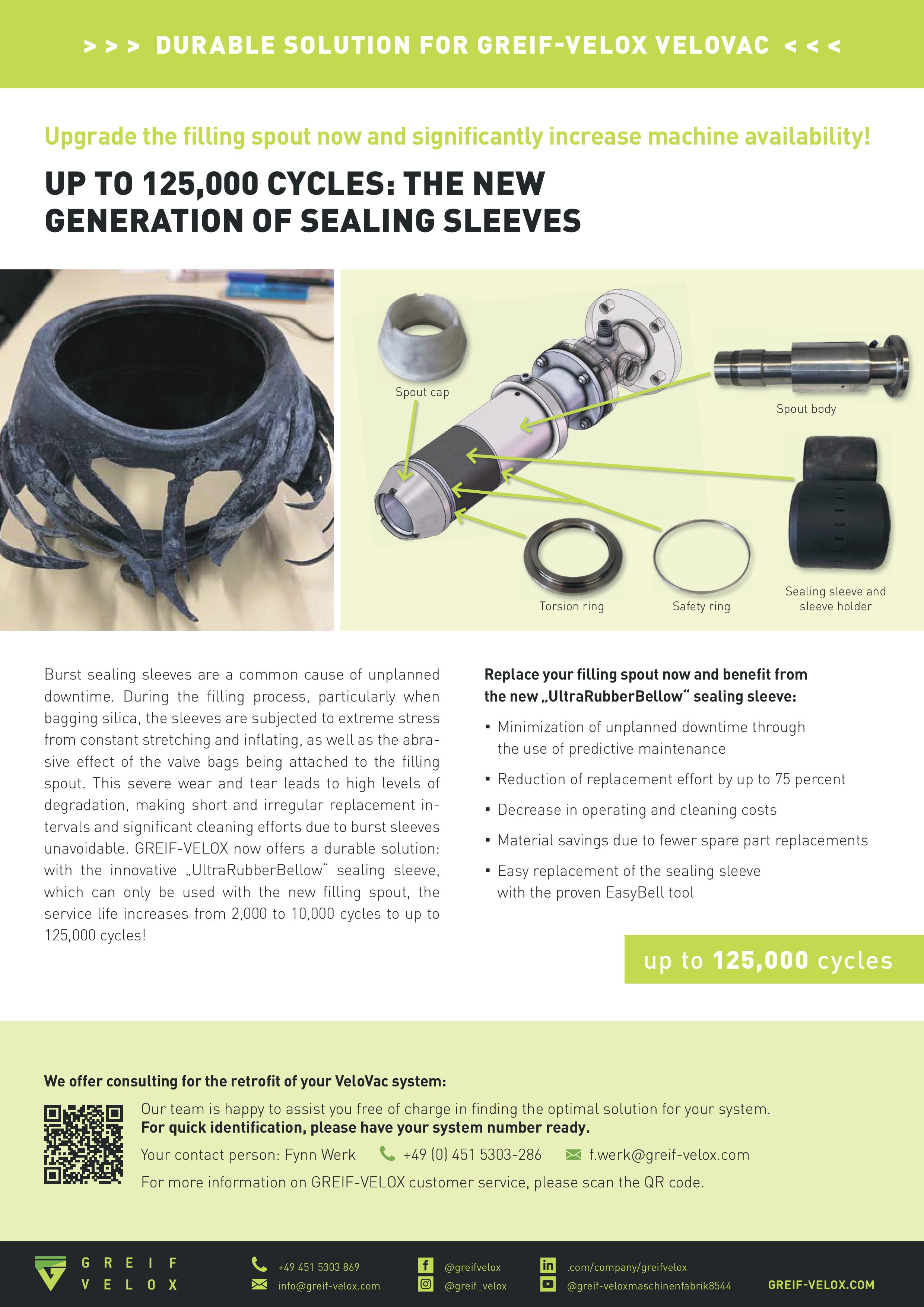

Up to 125,000 cycles: The new generation of sealing sleeves

download PDF

This is GREIF-VELOX: a pioneer of filling and packaging technology in 1,000 years of company history

EIR - Efficiency, innovation, reliability

are the cornerstones of our business philosophy

Reduction of operating costs

by reducing transport and logistics costs & saving cleaning and personnel costs

Optimization of production processes

by reducing downtimes, increasing production performance and data-supported process optimization

Improve security and compliance

by increasing employee and product safety

Innovation leadership in the filling and packaging industry

by integrating real-time data collection and Industry 4.0 concepts

Development of customer-specific solutions

through tailor-made adjustments based on specific customer needs, resulting in more efficient production processes

Promoting digital transformation

by using the latest digital tools and platforms for optimized and transparent production, increases productivity and reduces downtime

Maximum system availability

through robust design principles and continuous quality controls, resulting in lower failure rates and longer life cycles of the systems

Competent customer support

through rapid technical support & comprehensive maintenance programs, resulting in minimized downtime and optimized operations

Comprehensive security standards

through ongoing training and safety checks, ensures maximum safety for personnel and production

Click here to go directly to your service and spare parts contact

Direct contact to GREIF-VELOX: Here you will find your contact person.

Find your contact person