Technical highlights of the VeloPack

| Performance | Up to 1,200 bags/h |

|---|---|

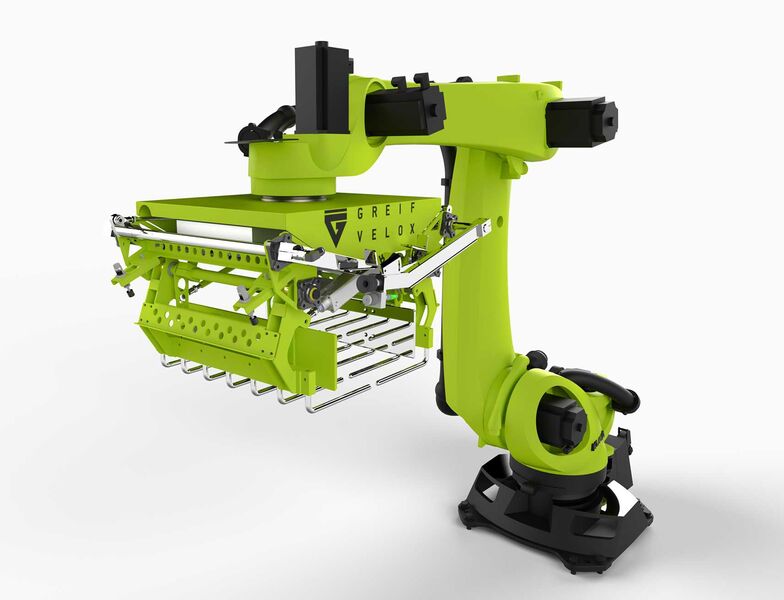

| Axis system | 5- or 6-axis robot with side grippers for maximum flexibility |

| Containers | Bags, drums, canisters, buckets, boxes |

| Load capacity | Up to 400 kg |

| Industries | Chemicals, Petrochemicals, food |

| Certifications | HI-compliant for the food industry |

| Application | Palletizing and depalletizing, handling of cover and interleaves, provision of empty pallets, ejection of faulty bags, transport of filled bags |

| Accessories | Automatic tool change system for quick changeovers, laser sensors for height detection, remote maintenance and HI lubricants (food-grade), cover sheet applicator and empty pallet magazines |

The VeloPack solves your production challenges when palletizing

Masterful palletizing

Manual palletizing inefficient and error-prone

Full automation increases efficiency by 30%

Unstable pallet loads

Precise robot control guarantees a clean pallet pattern

High space requirement

Compact design saves 20 % production space

Long changeover times

Modular system enables switching between products in < 30 minutes

Portal palletizer - automatic palletising for the highest demands

In contrast to the VeloPack, the portal palletiser is specially designed for handling plastic and steel drums; it optimises the palletising and depalletising of drums, operates at a lower throughput rate (up to 140 drums per hour) and impresses with its particularly robust and compact design, which is tailored to the specific requirements of industries such as chemicals, petrochemicals and food.

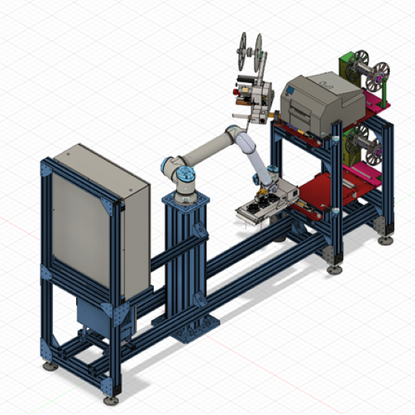

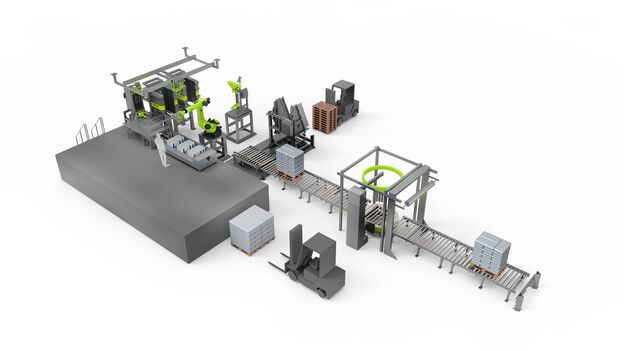

Portal palletizer in detailIntegrated full-line solutions

The VeloPack is part of turnkey systems that seamlessly combine conveyor technology, palletizing and load securing and can also be combined with stretch wrappers, edge protection systems and VeloFlexLabeler (automatic labelling) to provide a complete automation solution - tailored to your space and production volumes for optimum integration into your existing infrastructure.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each liquid filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

Further gripper Velox systems for palletizing & load securing